What is stainless steel welded pipes? After being coiled and molded by the unit and mold, stainless steel welded pipe, also known as welded pipe, is frequently welded into steel pipe made of steel or steel strip. It is a type of hollow strip ring stainless steel plate that is frequently used in projects involving crude oil, chemical plants, medical diagnosis and treatment, food, light industry, furniture production, landscape engineering, and other things.

What are the different types of stainless steel welded pipes?

There are two types of welded pipes: spiral welded pipe and straight seam welded pipe.

According to the use, it is divided into general welded pipe, heat exchanger tube, condenser tube, galvanized welded pipe, oxygen blow welded pipe, wire casing, metric welded pipe, idler pipe, deep well pump pipe, automotive pipe, transformer pipe, electric welded thin-walled pipe, electric welded special-shaped pipe and spiral welded pipe.

Product Specification and Characteristics

| Item | Stainless Steel Welded Pipe | |

| Grade | 304,316,309s,310s | |

| Standard | ASTM, DIN, GB, or customized size required by customers | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Type | hot rolled and cold rolled | |

| Size | Wall Thickness | 0.5~2.0mm |

| Outer Diameter | Ф10~Ф40mm | |

| Length Range | 0.5~30m | |

Economy and aesthetics: The general welded steel pipe has high precision, uniform wall thickness, and high brightness both inside and outside the pipe (the surface brightness of the steel pipe is determined by the surface grade of the steel plate), and can be fixed arbitrarily. The process of the product determines its advantages and disadvantages. As a result, it is affordable and attractive.

Good corrosion resistance: It is highly strong and, even if damaged, may be quickly repaired in an oxygen-rich atmosphere to stop rust. This is due to the thin protective film that covers its surface.

Distortion: Due to the site’s constraints on space, equipment, and construction personnel, stainless steel welded pipes are frequently used at construction sites without strictly adhering to construction specifications. For this reason, it is important to take into account the distortion factors at the connection between the pipe and the pipe fittings.

Economical benefit: Only roughly one-third of the thickness of the galvanized steel pipe is needed for usage because of the high corrosion resistance and mechanical qualities. As a result, the pipe is lighter, easier to handle, easier to apply, less expensive, and simpler to install.

In addition, the two types of welding are automatic welding and manual welding, depending on the technology used. Submerged arc welding and plasma welding are typically used in automatic welding, while argon arc welding is typically used in manual welding.

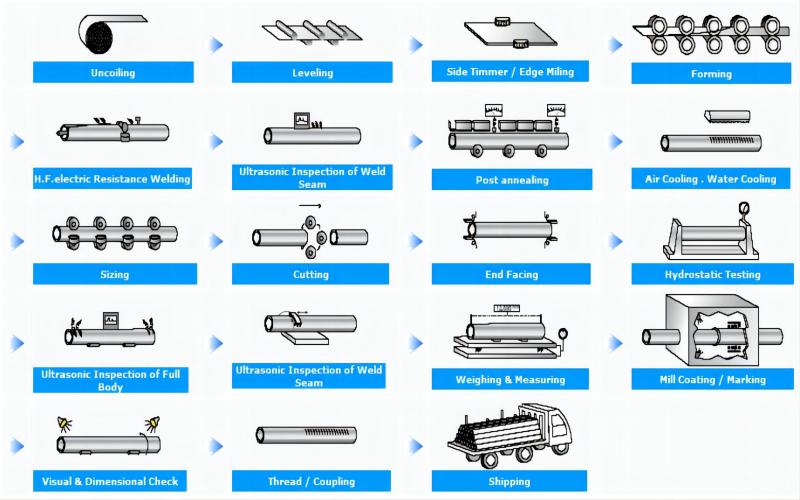

Product Manufacturing Process

Unwinding, cleaning equipment, feeding instructions, forming, welding, internal leveling of welds, external weld grinding, shape and sizing, solid melting treatment, final sizing, straightening, flaw identification, spray coding, sizing, cutting (coiling), splicing, etc.

What is the difference between seamless and welded stainless steel pipe?

Stainless steel welded pipe, also called stainless steel decorative pipe, the raw material is steel strip, steel strip is welded, and the inner wall will have a weld, its application is wide, mainly decoration, landscape engineering, furniture products, and other fields; The surface is normally matte or mirrored, and electroplating, painting, spraying and other processes are also used to give a layer of bright color on its surface.

Stainless steel seamless pipe is usually called industrial pipe, for the cold rolling or cold drawing process, the raw material is round steel, is round steel through the perforation into a pipe blank, and then the pipe blank and then one after another cold rolled or cold drawn; Its surface is normally sour white surface, that is, pickled surface, the surface requirements are not strict, the wall thickness is uneven, the brightness of the inner and outer surfaces of the tube is low, the fixed size cost is high, and the inner and outer surfaces should have pockmarks and black spots, which are not easy to remove.

In terms of qualities, seamless tubing typically has stronger strength because there are no welds, whereas welded tubing can also generate larger diameters with thinner walls. Although they might not be able to sustain as much pressure as seamless pipes, welded pipes are typically less expensive than seamless pipes.

Since the 1930s, the quality of welds has been continuously improved, the variety and specifications of welded steel pipes have increased, and seamless steel pipes have been replaced in an increasing number of fields, particularly in pipes for heat exchange equipment, decorative pipes, medium and low-pressure fluid pipes, etc. This is due to the rapid development of high-quality strip continuous rolling production and the advancement of welding and inspection technology.

Overall, both kinds of pipes have benefits and disadvantages, and the choice between them frequently depends on the particular application and specifications. When choosing between seamless and welded stainless steel pipes, it’s vital to take into account aspects like strength, price, pressure resistance, and manufacturing capabilities.

What is stainless steel welded pipe used for?

Welded steel pipe is produced using a straightforward method that is highly productive, offers several options and specifications, requires little equipment investment, and has a broad range of applications. Stainless steel welded pipes are frequently used in electric heating pipes, radiators, petrochemical, and other areas due to their great performance. The application area varies depending on the material.

Low-pressure fluid transportation: Because of its hollow shape and comparatively low weight, it is easy to handle, store, and install and is mostly used to transport low-pressure fluids including water, oil, gas, air, and steam.

Decoration: Because the protective film’s top layer is so hard, it has better acid and alkali corrosion resistance and good surface properties. This makes it popular for use as decorative pipes, prop tubes, and other objects like bathroom pipes, door handles, guardrails, chairs, and bed frames. It is also utilized while manufacturing furniture, along with other materials like marble and glass. Additionally, there will be bending for molding, which also puts a lot of strain on welding technology. Only a high-quality stainless steel pipe may be used to create stainless steel furniture with an original design and shape.

Mechanical and structural components: Due to its high temperature and corrosion resistance, it is widely employed in many industries and frequently used as mechanical and structural parts of machinery, vehicles, bicycles, and other items.

Welding Precautions

The inner wall of the stainless steel pipe is frequently unable to be pickled and passivated, which significantly reduces the corrosion resistance of the inner wall of the stainless steel pipe. When the stainless steel pipe is welded, the surface of the weld bead and the heat-affected zone is easy to oxidize and discolor, and it needs to be washed and passivated to form a dense oxide film on the surface. It is required to improve the welding process and take precautions to stop the back side from oxidizing and discoloring since the general welding process and construction procedures make it impossible to assure the welding quality of the rear weld and the heat-affected zone.

The welding current should not be too large, about 20% less than the carbon steel electrode, the arc should not be too long, the layer is quickly cooled, and the narrow welding bead is appropriate to prevent inter-eye corrosion due to heating, as an example, the electrode should be kept dry when used to prevent the electrode coating from sticking to oil and other dirt, in order to avoid increasing the carbon content of the weld and affecting the quality of the weldment.

Market Competition and Prospect

The consumption of stainless steel is rising along with the swift economic development in China, and stainless steel pipe demand is also rising. The market outlook is positive. With an estimated annual consumption of 700,000 tonnes, they are mostly utilized in heat exchanger pipes, fluid pipes, pressure pipes, mechanical structure pipes, urban landscapes, and other sectors. Industrial stainless steel welded pipes are in relatively high demand, and the manufacturing method is well-established. Overall, it has bright potential.

The Gnee Steel Group is a supply chain business that combines the design and manufacture of panels, pipes, and profiles with outdoor landscaping and the sales of small goods internationally. Since its founding in 2008, we have been committed to realizing the company’s mission of becoming the most competitive supply chain group in the world by providing exceptional, reliable, and cutting-edge services. After putting up many years of effort, Gnee Steel Group has emerged as the Central Plains’ most skilled steel supply chain international firm.