What is the difference between 316 and 316L pipes?

1. Price: Because 316L welded pipe has a lower carbon content and is easier to weld, it is slightly more expensive than 316 stainless steel welded pipe, although the difference is small. Furthermore, 316L welded pipe is also known as ultra-low carbon 316 stainless steel.

2. Corrosion resistance: Carbon (C) has a detrimental impact on the corrosion resistance of stainless steel welded pipes, particularly welded stainless steel welded pipes. Because 316L has a lower carbon content than 316, it has greater corrosion resistance and is appropriate for severely corrosive environments such as beaches and oceans.

3. Tensile strength: Because 316L has a tensile strength greater than 520MPa and 316 only has a tensile strength greater than 480MPa, 316L has a higher tensile strength than 316. This is because carbon is a strong austenitic element that can greatly boost the strength of stainless steel welded pipes.

4. Welding treatment: After welding, the 316 stainless steel welding section must be solution annealed. Solution annealing after welding is not necessary when using 316L welded pipe.

5. Application: The price difference between the two welded pipes is not considerable, and the corrosion resistance and weldability of 316L are significantly superior to that of standard 316 stainless steel welded pipes.

When the aforementioned criteria are considered, the current market circulation is primarily low-carbon 316L stainless steel welded pipe; the 316 welded pipe market is rarely seen unless there is a specific demand.

Product Specification, Characteristics, and Applications

| Item | 316L Stainless Steel Welded Pipe | |

| Standard | ASTM, DIN, GB, or customized size required by customers | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Type | hot rolled and cold rolled | |

| Size | Wall Thickness | 0.5~12mm |

| Length Range | 6m | |

1. Good weldability: It is simple to fuse using the classic melting technique and has high welding quality regardless of the filler metal used.

2. Broad range of applications: It has a wide range of applications in industries such as food and beverage, chemical and petrochemical, pharmaceutical, aerospace, and construction.

3. Corrosion resistance: 316L stainless steel welded pipe are appropriate for usage in tough chemical and moisture corrosion situations due to their strong corrosion resistance. As a result, it is frequently utilized in corrosive environments for oil storage and transportation, chemical reactors, seawater treatment, and pipeline systems.

4. Stainless steel pipes are suitable for applications that value cleanliness, such as environmental protection equipment, sewage treatment systems, and so on, because they are easy to maintain, clean, and non-corrosive.

5. Safe and clean: 316L stainless welded pipe meets hygiene requirements, is difficult for bacteria to grow on, and is safe to use. It is frequently utilized in food, medical, and other industries to manufacture seasoning storage tanks, cutlery, syringes, workstations, and so on.

6. Stunning appearance: polished and smooth surface, exquisite ornamentation, appropriate for architectural and indoor and outdoor decoration, such as railings, stair handrails, doors and windows, and so on.

7. High-temperature stability: can be utilized in burners, furnaces, turbine blades, spacecraft structures, and other applications that require high strength and oxidation resistance at high temperatures.

8. Biocompatibility: Because 316L welded pipe is biocompatible and does not irritate human tissues, it is extensively used in the production of medical equipment and gadgets such as ambulance stretchers, medical carts, operating room equipment, and so on.

Welding Methods of 316L Stainless Steel Welded Pipe

1. TIG welding: 316L stainless steel welded pipe requires penetration, no oxide inclusions, and a heat-affected zone as small as possible. TIG welding has good adaptability, high welding quality, and good welding penetration performance, so three-electrode torch argon arc welding is commonly used to improve welding speed. It has a welded steel pipe wall thickness of S2mm, a welding speed that is 3-4 times faster than a single welding torch, and enhanced welding quality. The combination of argon arc welding and plasma welding may weld steel pipes with thick walls; additionally, adding 5-10% hydrogen to argon and then utilizing a high-frequency pulse welding power source can boost welding speed.

2. Resistance welding: This is a way of heating the workpiece using the welding machine’s resistance heat, establishing a resistance between the two workpieces and generating a large contact pressure between the two poles. Resistance welding equipment is simple, easy to use, and simple to master. It is widely employed in manufacturing.

3. Gas shielded welding: Gas pollution prevention Arc welding is a form of welding that is closed by an arc. The arc has gas protection, the molten pool temperature is high, it is simple to generate a molten pool, the weld metal is difficult to oxidize and deoxidize, which can improve joint performance, joint quality is excellent, and the field of application is broad. It is commonly employed in high-temperature and high-pressure environments. It is appropriate for welding complex workpiece constructions such as pressure tanks and boilers.

Overall, the operating procedure of 316L stainless steel pipe has a significant impact on weld quality. In welding operations, we must pay close attention to temperature management to avoid cracks and other problems in the weld caused by high heat. The pipeline should be kept clean and neat, and welding slag, oxide scale, and flux should be cleaned regularly. Otherwise, these substances will degrade the weld quality. These compounds must be removed with a grinding wheel if they are mistakenly left on the weld.

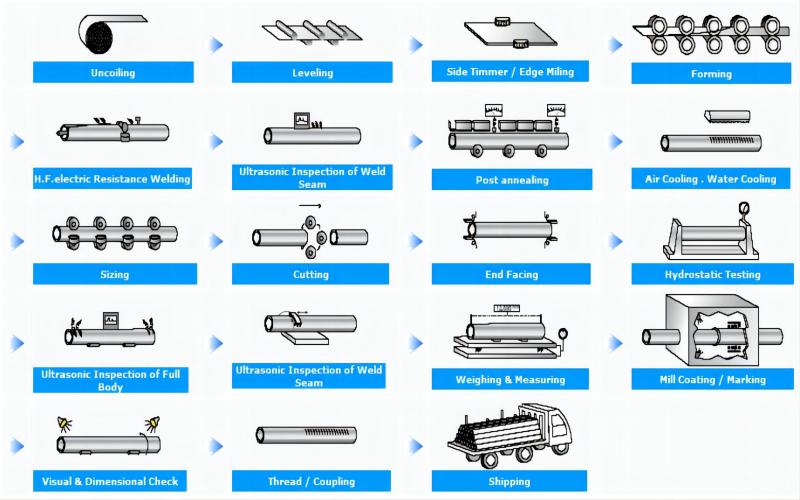

Manufacturing process of 316L Stainless Steel Welded Pipe

1. Choose raw materials.

2. Raw materials are sheared, sawed, or laser cut to the appropriate size.

3. Using various procedures such as rolling, bending, or welding, shape the cut into a tubular shape.

4. Weld the molded sections together using one of the various welding procedures to assure the final product’s structural integrity.

5. Heat treat the welded pipe to improve the material’s strength and longevity and minimize residual tension in the welded connection.

6. The finished product is extensively tested and examined to ensure it satisfies the needed parameters, such as dimensional accuracy, strength, corrosion resistance, and overall industry conformity.

Market and Competitive Conditions

The overall strength and product quality of the providers, market demand, and the number and intensity of competitors all have an impact on the competitiveness of the market for 316L stainless steel welded pipe. First, there is a significant degree of competition due to the increased number of providers on the market. Quality and property are therefore essential for preserving market competition. From a different perspective, brand awareness, variations in demand between regions and industries, and other factors have an impact on the competitive environment and market share.

To remain competitive, suppliers must continually improve the quality of their products, reduce costs, provide distinctive services, and grow their markets.

The Gnee Steel Group is a supply chain firm that combines panel design and processing, pipes and profiles, outdoor landscaping, and overseas small product sales. It was founded in 2008 to be the most competitive supply chain group in the world; since then, we have been committed to achieving that goal with great, consistent, and creative services. The Gnee Steel Group has become the most professional steel supply chain worldwide firm in the Central Plains after many years of hard labor.