A steel pipe made of seamless stainless steel is resistant to chemically aggressive media like acid, alkali, and salt as well as weak corrosive media like air, steam, and water. Stainless acid-resistant steel pipe is another name for it. It is a hollow long round steel that resists corrosion following the alloying components that are present in the steel.

What is the difference between seamless and welded stainless steel pipe?

Stainless steel welded pipe, also called stainless steel decorative pipe, the raw material is steel strip, steel strip is welded, and the inner wall will have a weld, its application is wide, mainly decoration, landscape engineering, furniture products, and other fields; The surface is normally matte or mirrored, and electroplating, painting, spraying and other processes are also used to give a layer of bright color on its surface.

Stainless steel seamless pipe is usually called industrial pipe, for the cold rolling or cold drawing process, the raw material is round steel, is round steel through the perforation into a pipe blank, and then the pipe blank and then one after another cold rolled or cold drawn; Its surface is normally sour white surface, that is, pickled surface, the surface requirements are not strict, the wall thickness is uneven, the brightness of the inner and outer surfaces of the tube is low, the fixed size cost is high, and the inner and outer surfaces should have pockmarks and black spots, which are not easy to remove.

In terms of qualities, seamless tubing typically has stronger strength because there are no welds, whereas welded tubing can also generate larger diameters with thinner walls. Although they might not be able to sustain as much pressure as seamless pipes, welded pipes are typically less expensive than seamless pipes.

Overall, both kinds of pipes have benefits and disadvantages, and the choice between them frequently depends on the particular application and specifications. When choosing between seamless and welded stainless steel pipes, it’s vital to take into account aspects like strength, price, pressure resistance, and manufacturing capabilities.

What are the different types of seamless steel pipe?

| Item | Stainless Steel Seamless Pipe

|

| Wall Thickness | Thin-walled steel pipe, thick-walled steel pipe |

| Section Shape | Round, special shape |

| Production Method | Hot rolled pipe, cold rolled pipe, cold drawn pipe, extruded pipe, jacking pipe |

| Application | for thermal equipment, for the machinery industry, for the chemical industry, for special purposes, etc. |

| Dimension

|

Standard size(ASTM、DIN、GB), customized size required by customers. |

Product Specification and Characteristics

Standard: Among the often-used specifications are ASTM A312, A213, A269, and A789. The dimensions, tolerances, and material characteristics of the seamless stainless steel pipe are all specified in these standards. The most frequently mentioned standard is ASTM A312, which describes austenitic stainless steel tubing that is seamless, welded, and heavily cold-worked and intended for use in high-temperature and generally corrosive environments.

Characteristics: First, the more affordable and useful the wall thickness, the thicker the wall thickness, and the more expensive the processing, the smaller the wall thickness. Second, the inner and outer surfaces of the tube have pockmarks and black spots that are difficult to remove, the brightness of the inner and outer surfaces is low, and the cost of sizing is high. Third, the wall thickness is irregular.

| Item | Stainless Steel Seamless Pipe

|

|

| Grade | 304,309,310,316L | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Size | Wall Thickness | 0.5~40mm |

| Outer Diameter | 6mm~610mm | |

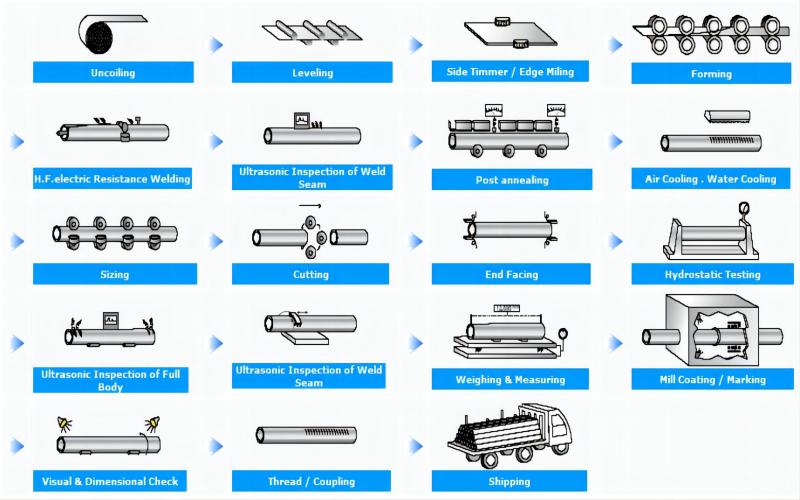

Product Manufacturing Process

The manufacturing processes of 304 stainless steel seamless pipe are as follows: round bar preparation, heating, hot rolled perforation, head cutting, acid pickling, regrinding, degreasing, cold rolling processing, solution heat treatment, straightening, tube cutting, acid pickling, and finished product inspection.

Applications and Advantages of Stainless Steel Seamless Pipe

Food and beverage industry: Stainless steel is a preferred material for applications involving food and beverages because of its corrosion resistance. For instance, water pipelines and lunch boxes.

Industry of oil and gas: Oil, gas, and other fluids are transported via seamless steel pipes in this sector. a building’s water supply and drainage system, for instance.

Industries involving mechanical engineering: Stainless steel seamless pipes are employed in a range of mechanical engineering applications, including pressure vessels, heat exchangers, and boilers. Barrels and shells are two examples. Its three key benefits are that it is corrosion-resistant, safe, and trustworthy, and that it has a wide variety of applications. First, seamless steel pipe has better corrosion resistance and higher tensile strength than welded pipe because stainless steel is a high-quality material compared to other steels. Second, there is no interface, making seamless steel pipe more reliable and durable than welded pipe. Third, the application range is particularly broad, including pipelines, auto manufacturing, and other industries. In conclusion, a seamless stainless steel pipe is a great option.

Market Competition and Prospect

With the advent of global urbanization, there is a growing need for infrastructure construction, which is steadily driving up demand for stainless steel seamless pipe as a significant pipe material. On the other hand, environmental protection is a hot concern globally, and sustainable development is a general trend. As a result, more and more fields are gravitating towards picking materials that adhere to these standards. The demand for stainless steel seamless pipe will rise as a result of its excellent corrosion resistance and hygiene, which are consistent with the idea of environmental protection.

Additionally, stainless steel seamless pipes have significant uses in the petrochemical, chemical, and energy industries. As a result, their potential is very vast. To summarize, the market players in the highly competitive stainless steel seamless pipe business must be conscious of this and strive to set themselves apart from the competition.

The Gnee Steel Group is a supply chain business that combines the design and manufacture of panels, pipes, and profiles with outdoor landscaping and the sales of small goods internationally. Since its founding in 2008, we have been committed to realizing the company’s mission of becoming the most competitive supply chain group in the world by providing exceptional, reliable, and cutting-edge services. After putting up many years of effort, Gnee Steel Group has emerged as the Central Plains’ most skilled steel supply chain international firm.