Advantages and disadvantages of 304 stainless steel

The benefits are as follows:

Strong corrosion resistance: Because 304 stainless steel includes 18% chromium and 8% nickel, it has good corrosion resistance, can withstand most chemical erosion, is not easily rusted, and is appropriate for the manufacture of a wide range of corrosion-resistant equipment and appliances. However, corrosion resistance is lower when compared to 316 stainless steel.

Good processing performance: 304 stainless steel is simple to process, form, and weld, and it can be used to create a wide range of products due to its plasticity and machinability.

Good strength and wear resistance: 304 stainless steel is strong and wear-resistant, making it ideal for high-strength parts and mechanical equipment.

The drawbacks are as follows:

The surface of 304 stainless steel is relatively soft, easy to scratch and wear, and must be used and maintained with caution.

High-temperature resistance: 304 stainless steel has poor high-temperature resistance and is only appropriate for usage in low and normal-temperature situations.

What is the difference between 304 and 316?

Chemical composition: Molybdenum is present in 316 but not in 304.

Corrosion resistance: Because 304 has less nickel than 316, it is less corrosion resistant.

Because of the inclusion of molybdenum, 316 has increased corrosion and heat resistance.

While 304 is commonly used in the fabrication of pots and pans, 316 is commonly employed in the food, medical, watch, and other industries.

Price: Because 316 is food grade and has higher corrosion resistance, it will be more expensive than 304.

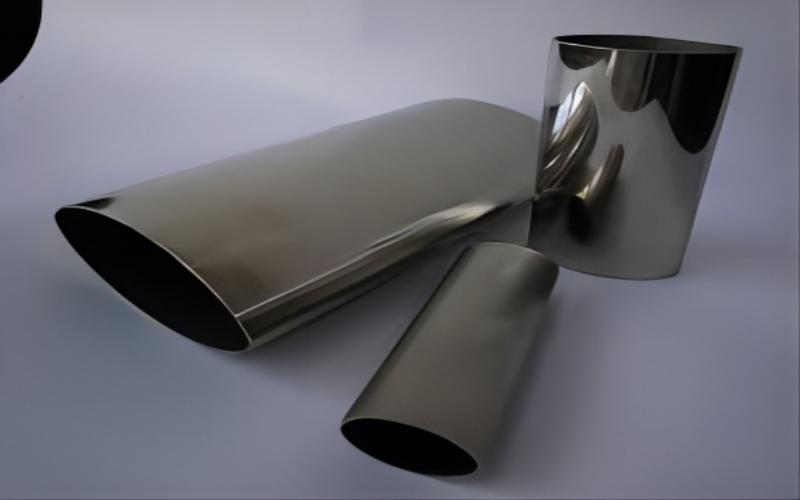

Product Specification, Characteristics, and Application

| Item | 304 Stainless Steel Oval Pipe | |

| Standard | ASTM, DIN, GB, or customized size required by customers. | |

| Material | C, Fe, Mo, Mn, Si, N, etc. | |

| Size | Wall Thickness | 0.3mm~5mm |

| Outer Diameter | 6mm~100mm | |

| Inner Diameter | 3mm~80mm | |

1. Corrosion resistance: Because it is corrosion resistant in both oxidizing and reducing environments, it is a popular choice for chemical processing and other corrosive environments like heat exchangers, furnaces, petrochemical equipment, conduits, masts, anchor chains, distillation columns, storage tanks, and so on.

2. Heat resistance: Due to its outstanding heat resistance, it is suitable for high-temperature applications such as furnaces, burners, and pipelines.

3. They are suitable for applications that value cleanliness, such as environmental protection equipment, sewage treatment systems, and so on, because they are simple to maintain, clean, and non-corrosive.

4. Hygiene standards are met, bacteria cannot grow on stainless steel oval pipe, and it is fully safe to use. It is commonly utilized in food, medical, and other industries to manufacture spice storage tanks, cutlery, syringes, workstations, and other products.

5. Gaceful and long-lasting: 304 stainless steel oval tube has a smooth look and graceful lines, making it perfect for all types of architectural decoration and furniture manufacture.

What is the difference between round and oval pipes?

A round tube’s cross-sectional form is round, whereas an elliptical tube’s cross-sectional shape is oval or flat-sided oval. Round pipes have a consistent cross-section and are suited for a wide range of fluid transport and structural applications. The elliptical tube has a distinct appearance and graceful lines, making it ideal for a variety of decorative and structural applications.

Round tubes have a basic appearance and a homogeneous circular cross-section, making them popular in typical industrial applications. The elliptical tube has a unique and lovely appearance, with an oval section, and is frequently employed in architectural decorating, furniture production, and other occasions requiring art.

Flow efficiency: Flow efficiency and heat transfer properties may differ between the two geometries. According to some measurements, elliptical pipes have less boundary layer air buildup than circular pipes and can flow more air at the same pressure.

Noise transfer: Oval pipes may transmit less noise between rooms or locations, but circular pipes may convey more noise.

The primary distinction between round and oval pipes is their shape, but there may be changes in conveying capacity, noise transfer, and flow efficiency as well.

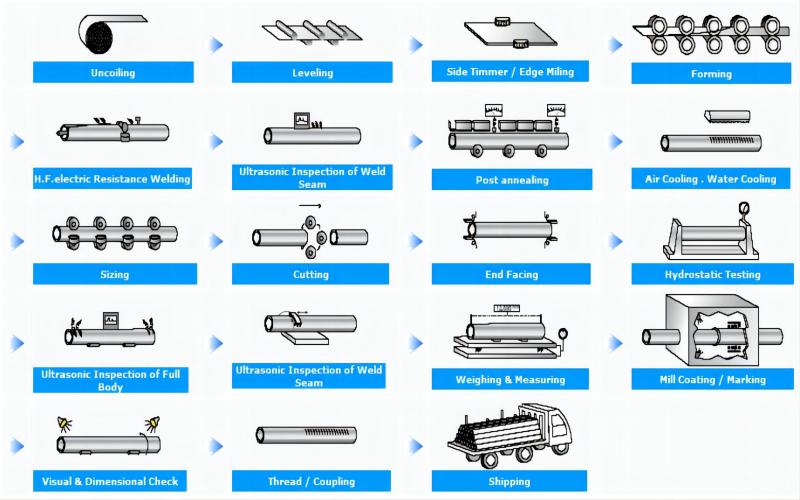

Product Manufacturing Process

1. Raw material selection: Depending on the necessary mechanical, corrosion, and temperature resistance capabilities.

2. Tube formation: To create the oval tube from a flat sheet or strip of stainless steel, manufacturers may employ a variety of tube forming techniques such as roll forming, press bending, or rotary drawing.

3. Welding: To combine the two ends of the oval tube and ensure a continuous and smooth surface, manufacturers may employ various welding processes such as TIG or laser welding.

4. Heat treatment: Depending on the desired material qualities, some producers may subject the stainless steel oval tube to heat treatment methods such as annealing or quenching, and tempering to improve mechanical, thermal, or corrosion resistance.

5. Finishing: To obtain the desired look and surface quality of the stainless steel oval pipe, manufacturers may use several finishing procedures such as polishing or satin finishing.

Market Competition and Prospect

Stainless steel is widely employed in a variety of industries, including construction, manufacturing, automotive, and aerospace. Because of its outstanding corrosion resistance, durability, and adaptability, 304 stainless steel is one of the most often used grades in the stainless steel category. While oval pipes are not as prevalent as round pipes, their shape may be helpful in some applications such as handrails, exhaust systems, or aesthetic design. As a result, elliptical pipe market rivalry may vary depending on the exact application, geographical region, and competition from other materials or forms.

Finally, the worldwide stainless steel market is predicted to expand in the coming years, owing to factors such as urbanization, infrastructure expenditure, and rising demand for environmentally friendly materials.

The Gnee Steel Group is a supply chain firm that combines panel design and processing, pipes and profiles, outdoor landscaping, and overseas small product sales. It was founded in 2008 to be the most competitive supply chain group in the world; since then, we have been committed to achieving that goal with great, consistent, and creative services. The Gnee Steel Group has become the most professional steel supply chain worldwide firm in the Central Plains after many years of hard labor.