Stainless steel tee and cross pipe fittings are a kind of stainless steel pipe fittings. The connecting pipe fittings made of stainless steel have the characteristics of corrosion resistance, high temperature resistance and high strength. They are widely used in chemical, petroleum and other fields.

What is stainless steel three-way, four-way pipe fitting?

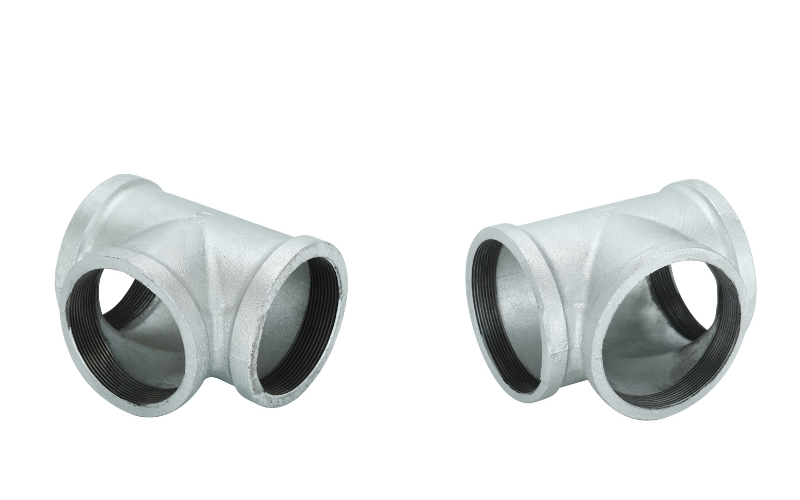

Stainless steel tee fittings, also known as stainless steel tees, are made of stainless steel and are used to connect two pipes. Stainless steel tee fittings are generally “T” type. According to the pipe diameter, it can be divided into equal diameter tee and different diameter tee.

Stainless steel four-way pipe fittings are also known as stainless steel four-way and cross-way, usually made of stainless steel as raw materials, and are used to connect four pipes with the same diameter and vertical intersection. This structural design makes the stainless steel four-way pipe fitting suitable for some complex pipe systems.

Stainless steel three, four pipe fitting implementation standards and materials

The implementation standards of tee stainless steel pipe fittings include: GB/T12459, GB/T13401, HG/T21635, HG/T21631, SY5010, SH3408, SH3409, ASME/ANSI, B16.9 JIS B2311/2312/2313, DIN2605/2615/2616/2617, etc

The materials of tee stainless steel pipe fittings include:

ASTM:304, 304L, 316, 316L, 316Ti, 317, 317L, 321, 321H, etc

JIS:SUS304, SUS304L, SUS316, SUS316L, SUS316Ti, SUS317L, SUS321, SUS321H, etc

DIN:1.4301, 1.4306, 1.4401, 1.4435, 1.4571, 1.4436, 1.4438, 1.4541, etc

The implementation standards of tee stainless steel pipe fittings include: GB/T 12459, GB/T 14383, JB/T 1752, ASTM A403 / ASME SA403, ASTM A815 / ASME SA815, JIS B2311, ISO 4144, etc

Materials for four-way stainless steel pipe fittings include:

ASTM:304,304l,316,316l,321,etc

GB: 0Cr18Ni9, 0Cr17Ni12Mo2, 0Cr18Ni10Ti,etc

JIS:SUS304,SUS316,SUS321,etc

What are the types of stainless steel three and four pipe fittings?

Classification of stainless steel tee pipe fittings:

According to the diameter of the pipe can be divided into: diameter tee and reducing tee.

According to the docking method can be divided into: butt welding type, socket type, sleeve type, spiral pattern four.

Classification of stainless steel four-way fittings:

According to the diameter of the pipe, it can be divided into: stainless steel equal-diameter four-way, stainless steel different-diameter four-level

According to the production method, it can be divided into: top system, pressing, forging, casting, etc.

According to the butt joint method, it can be divided into: welded butt joint, threaded butt joint, flange butt joint, joint butt joint, etc.

Stainless steel three-way, four-way pipe fittings manufacturing process

Stainless steel tee pipe production process: raw material preparation – material cutting – forming – heat treatment – welding – surface treatment – inspection and testing – packaging and labeling – factory

Stainless steel four-way pipe production process: raw material preparation – blanking – processing – hydraulic forming – cutting port – heat treatment – groove treatment – quality inspection – packaging label – factory

What is the difference between stainless steel three-way and four-way pipe fittings?

Stainless steel tees and crosses have certain differences in shape and use:

The difference in structural shape: the stainless steel three-way fitting is connected by a main pipe and two shunt pipes, and the pipe is in the shape of “T” or “Y”, while the stainless steel four-way fitting is composed of a main pipe and three shunt pipes, and the pipe is in the shape of “十” font.

The difference in the number of connections: stainless steel tee fittings have three connections, while stainless steel cross fittings have four connections.

Differences in the scope of application: stainless steel tee fittings are suitable for some simpler piping systems, such as water supply pipes, heating pipes, food industry, etc.; stainless steel cross fittings are often used in piping systems that require more diversion and confluence capabilities, such as chemical, petroleum and other fields.

The difference in pipe design: the use of stainless steel tee joints requires careful design of the pipe joints; the use of stainless steel cross joints can provide more ports and make the pipe design more flexible.

What are the applications of stainless steel tee and four-way fittings?

Use of stainless steel tee pipe fitting:

1,the use in the chemical industry: often used in the chemical production process of diversion, confluence and other processes in the pipeline system.

2, the use in the natural gas industry: often used to connect pipeline branches, change the direction of the pipeline, etc.

3, the use in the food processing industry: often used in the food processing process of mixing, distribution and other systems, as well as food transportation pipeline system.

- Use in the Marine industry: It is often used in the connection of shunt and confluence pipes in the Marine drainage and cooling system.

Use of stainless steel four-way pipe fitting:

- Use in the natural gas industry: It is often used for diverting, confluence and changing the direction of pipelines.

2, Use in the chemical industry: often used in pipe system control and fluid flow distribution.

3, the use of sewage treatment: often used in treatment stations, sewage treatment equipment and pipeline systems, for shunt, confluence and change the flow of sewage and so on.

4, the use in the power generation industry: commonly used as a power plant circulating water system, cooling system, etc., to achieve the flow of fluid shunt, confluence and change the direction of the pipeline.

The difference between stainless steel equal diameter tee and different diameter tee

Equal diameter stainless steel tee fittings and reducing diameter stainless steel tee fittings are common pipe connections, but they have obvious differences:

1, The diameter of the diversion pipe is different: the diameter of the shunt pipe of the equal-diameter tee is the same as that of the main pipe, and the diameter of the shunt pipe of the different-diameter tee is larger than that of the main pipe.

2, The flow distribution is different: the diameter of the equal-diameter shunt pipe is the same as that of the main pipe, and the flow rate remains unchanged, while the diameter of the shunt pipe of the variable-diameter pipe is larger than that of the main pipe. The flow distribution of the main pipe is uneven.

3, Different pipe connection methods: the equal-diameter tee can be connected by welding, thread, or flange, and the different-diameter tee can be connected by welding, ferrule, ferrule, etc.

4, Different uses: Equal diameter tees are widely used in occasions where liquids diverge, merge or change the direction of pipelines, such as chemical industry, water treatment systems, etc., while reducing tees are usually used to adjust fluid flow and control flow.