What Is Stainless Steel?

In the field of metallurgy and materials science, stainless steel is defined as a type of steel that takes corrosion resistance and stainlessness as the main performance. Additionally, it must contain a chromium content of at least 10.5% and a carbon content of no more than 1.2%. The chromium creates a protective oxide layer on the surface, which is a self-healing oxygen barrier that stops further oxidation. Below 10.5% chromium, the oxide film is of insufficient durability to be self-healing.

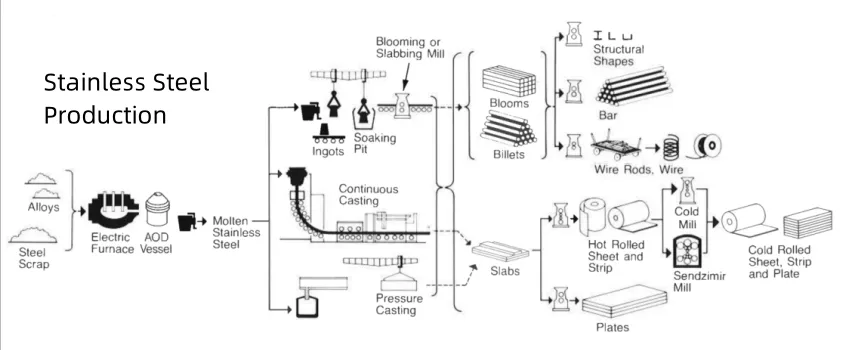

How Is Stainless Steel Made?

Here are some important steps to be observed:

Step 1: Melting

It starts with melting scrap metals and additives in an electric arc furnace (EAF).

Step 2: Removing Carbon Content

Carbon helps to increase the hardness and strength of iron. However, too much carbon can create problems—such as carbide precipitation during welding. Before casting molten stainless steel, calibration and reduction of carbon content to the proper level is essential.

There are two ways foundries control carbon content.

The first is through Argon Oxygen Decarburization (AOD). Injecting an argon gas mixture into the molten steel reduces carbon content with minimal loss of other essential elements.

The other method used is Vacuum Oxygen Decarburization (VOD). In this method, molten steel is transferred to another chamber where oxygen is injected into the steel while heat is applied. A vacuum then removes vented gases from the chamber, further reducing carbon content.

Both methods offer precise control of carbon content to ensure a proper mixture and exact characteristics in the final stainless steel product.

Step 3: Tuning

After reducing carbon, a final balancing and homogenization of temperature and chemistry occurs. This ensures that the metal meets requirements for its intended grade and that the steel’s composition is consistent throughout the batch.

Samples are tested and analyzed. Adjustments are then made until the mixture meets the required standard.

Step 4: Forming or Casting

With the molten steel created, the foundry must now create the primitive shape used to cool and work the steel. The exact shape and dimensions will depend on the final product.

What Are the Different Types of Stainless Steel?

Stainless steel can be divided into different types according to different classification standards. Let’s see together.

1. Chemical Component

According to the main chemical components in stainless steel, it can be divided into two categories:

Chromium Series Stainless Steel: besides iron, the main alloying element in stainless steel is chromium.

Chromium-nickel Series Stainless Steel: besides iron, the main alloying elements in stainless steel are chromium and nickel.

2. Organizational Structure

Stainless steel can be divided into five categories according to its organizational structure. They are:

Austenitic Stainless Steel: mainly comprised of nickel and molybdenum contents and has a face-centered cubic crystal structure. The addition of nickel increases its corrosion resistance and ductility, while molybdenum improves corrosion resistance to acidic conditions. Common grades of austenitic stainless steel are 304 and 316.

Martensitic Stainless Steel: mainly uses carbon and chromium as the main alloying elements. At higher carbon concentrations, the material has a body-centered tetragonal crystal structure; lower carbon concentrations form a body-centered crystal structure. Martensite is formed when austenite is quenched rapidly at room temperature. Martensitic stainless steel is commonly known as the 400 series of stainless steel, such as grades 410, 420, and 440.

Ferritic Stainless Steel: is non-magnetic and has a body-centered cubic crystal structure. Its main alloying constituents are chromium, iron (hence the name ferritic), and a low concentration of carbon. Ferritic stainless steel is, therefore, softer, but also has increased ductility and improved formability — but they cannot be heat treated. Examples of ferritic stainless steel are other 400 series grades, such as 409, 430, and 446.

Duplex Stainless Steel: a combination of austenitic and ferritic stainless steels, with a carefully tuned proportion of both types of crystalline structure. They offer higher strength combined with great corrosion resistance and are often used in chemical processing and oil and gas applications.

Precipitation-hardening Stainless Steel: is achieved by the formation of small particles, precipitated within the material, that increase its strength and hardness by inducing lattice stress. This can commonly deliver 3–4 times the strength of basic austenitic stainless steel.

What Are the Benefits of Stainless Steel?

1. Superior Corrosion Resistance: it is highly resistant to corrosion and rust due to the presence of chromium in the alloy. This makes it suitable for use in harsh environments, such as marine or chemical applications.

2. Great Durability: stainless steel is a strong and durable material with a high strength-to-weight ratio. It is resistant to deformation and can withstand high stress without breaking or cracking, making it suitable for use in demanding applications.

3. Appealing Appearance: it lends a modern and sleeking appearance to many applications, being essentially unchanging and maintenance-free in the great majority of applications.

4. Good Weldability: Most stainless steel alloys are highly weldable, making the assembly of complex systems from individual parts a clean, watertight, and permanent process.

5. Good Formability: Being generally fairly malleable materials and in many cases of moderate to high ductility, stainless steels provide many options in manufacturing processes that allow the manufacture of complex and intricate components for a wide range of purposes.

6. High-temperature Resistance: It can withstand high temperatures without degrading.

7. Sustainable Material: it is 100% recyclable without loss or degradation.

8. Easy Cleanliness and Maintenance: stainless steel is easy to clean and maintain. The smooth finish gives dirt and germs nowhere to hide. Correspondingly, it reduces maintenance costs.

What Are the Limitations of Stainless Steel?

The main limitation of stainless steel may be the one that it is more expensive than other materials, such as carbon steel or aluminum, depending on the specific grade and application.

However, if the resale value stays high, you can recoup some of the cost if you do sell.

Where Is Stainless Steel Used In?

Stainless steel can be said a part of everyday life. It can be used in construction, machinery, medical equipment, food processing, power plants, civil engineering, shipbuilding, energy, etc. Whether it’s the knife and fork you use or the oil you put in your car, stainless steel has probably had a direct or indirect impact on what you do.

Sourcing Simplified – Start Your Next Stainless Steel Project With Gnee Steel

For all your stainless steel manufacturing and finishing needs, Gnee has you covered. We’re experts at producing stainless steel products and parts in a variety of thicknesses, sizes, shapes, grades, and finishes. The common series includes stainless steel plates, stainless steel pipes, stainless steel coils, stainless steel foils, stainless steel pipe fittings, stainless steel profiles, etc.

Choose Gnee Steel! We can be your one-stop stainless steel supplier that makes SS fabrications faster, easier, and more efficient.