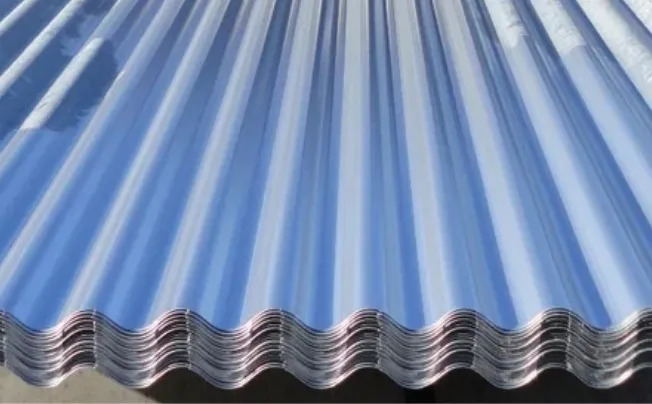

316 Stainless Steel Corrugated Plate Definition

Generally speaking, 316 Stainless steel corrugated plate is made of 316 stainless steel plates, rolled into various forms of corrugated patterns by cold bending. 316 stainless steel is part of the austenitic stainless steel family and is the second most widely used stainless steel grade. It contains a higher level of nickel than 304 stainless steel, which enhances its mechanical ability to withstand high temperatures and improve its corrosion resistance over 304.

316 Chemical Composition

| C | Cr | Mo | Si | P | S | Ni | Mn | N |

| 0.0 – 0.07% | 16.50 – 18.50% | 2.00 – 2.50% | 0.0 – 1.00% | 0.0 – 0.05% | 0.0 – 0.02% | 10.00 – 13.00% | 0.0 – 2.00% | 0.0 – 0.11% |

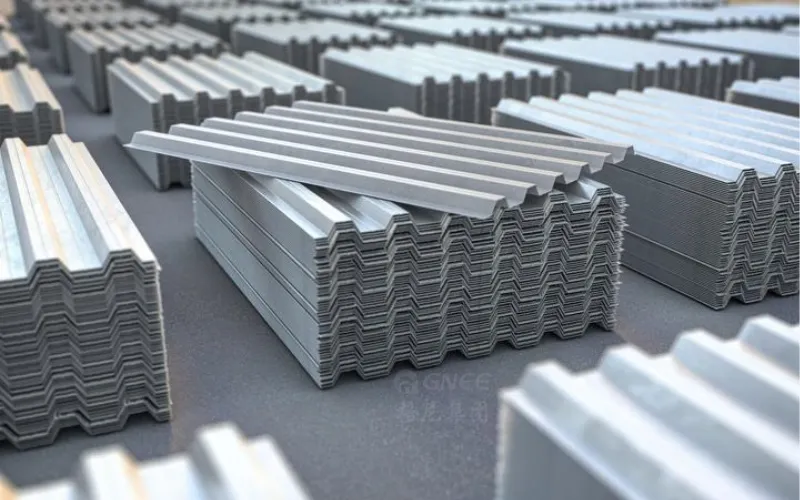

316 Stainless Steel Corrugated Plate Specification

| Material | stainless steel plate |

| Grade | 316 |

| Standard | JIS, AISI, ASTM, GB, DIN, EN |

| Thickness | 0.2 – 12 mm |

| Width | 600 – 1500 mm (support customization) |

| Length | 800 – 5000 mm (support customization) |

| Tolerance | ±1% |

| Finish | brushed, color coated, sandblasted, polished, etc |

| Technique | cold rolled |

| Packing | PVC + waterproof or paper + wooden package |

316 Stainless Steel Corrugated Plate Features

Stainless steel corrugated plates made of 316 grade offer various features, rendering them highly desirable for different applications. These include:

1. Superior Corrosion Resistance

316 stainless steel has superior corrosion resistance than 304 stainless steel corrugated plates. The addition of molybdenum further fortifies its resistance against the insidious forces of pitting and crevice corrosion. Even in chloride-rich environments, such as marine environs or industrial settings teeming with hazardous chemicals, it can resist helpfully.

2. High Strength

It is endowed with high strength and great durability, which can withstand the most arduous of burdens and the most formidable of mechanical stresses. This high strength, when combined with its corrosion resistance, renders the 316 stainless steel corrugated plates the epitome of excellence for applications that demand both structural integrity and longevity.

3. Heat Resistance

Another notable attribute of the 316 stainless steel corrugated plate is its heat resistance. Unfazed by elevated temperatures, the plate can retain its structural integrity and mechanical properties, standing firm and resolute in the face of searing thermal conditions. This property makes it the ideal choice for applying in high-temperature environments, such as the crucibles of heat exchangers, boilers, or exhaust systems.

4. Easy Forming

It has excellent forming and welding characteristics and can be readily brake or roll formed into a variety of parts for applications in the industrial, architectural, and transportation fields.

5. Good Decorative Properties

It has a harmonious blend of durability and vibrant aesthetics. What’s more, it can be colored to add a touch of modern elegance, making it an ideal choice for roofing applications in diverse settings.

6. Easy Maintenance

Possessing a surface as smooth as the finest silk, these plates repel dirt, debris, and other unsightly contaminants, making them a breeze to cleanse. Furthermore, their unwavering resistance to corrosion minimizes the need for frequent maintenance or arduous repairs.

316 Stainless Steel Corrugated Plate Applications

Due to its corrosion resistance, heat resistance, and high strength, it is suitable for industries such as industrial, architectural, transportation, and food processing fields.

1. Construction and Architecture

It is often employed for roofing, wall cladding, and structural components in edifices and infrastructure projects. The material’s ability to withstand the harshest environmental conditions, including exposure to moisture, chemicals, and extreme temperatures, renders it the preferred choice for architectural designs.

2. Industrial and Manufacturing

Due to its remarkable resistance to corrosion and high temperatures, 316 stainless steel corrugated plate is ideal for employment in chemical processing plants, oil and gas refineries, and power generation facilities. The material’s strength and ductility also render it suitable for the fabrication of equipment and machinery components that require unwavering reliability, such as heat exchangers, pressure vessels, and storage tanks.

3. Transportation and Automotive

It can be used in the production of parts and components in ships, railways, airplanes, and automobiles. From exhaust systems and fuel tanks to structural components and fasteners, this material ensures longevity and safety in the transportation industry.

4. Food Processing and Packaging

It is commonly applied in the fabrication of equipment such as tanks, pipes, and conveyors, which come into direct contact with food products. The material’s smooth surface and ease of cleaning also contribute to the maintenance of impeccable levels of cleanliness and safety in food processing facilities.

5. Public Uses

It is also widely used in kitchen and sanitarywares, furniture handles, handrails, electroplating and electrolyzing pendants, warehouses, refrigeration, piping and ducting, filtration, shelters, and metal jacketing.

316 SS Corrugated Plate Installation and Maintenance

1. Proper Installation Techniques

During installation, it is important to ensure a clean and dry surface, use appropriate adhesives or fasteners, and consider environmental conditions and potential stresses.

2. Cleaning and Maintenance Guidelines

Regular cleaning with mild soapy water or specialized stainless steel cleaners, avoiding abrasive materials or harsh chemicals, and conducting regular inspections are important for maintenance.

3. Asking Professionals for Help

Our company, Gnee Steel, is a professional roofing sheet distributor, seller, and exporter among famous manufacturers and suppliers in China. If you have any questions, contact us directly. Please email to [email protected].