410 Stainless Steel Punching Plate Introduction

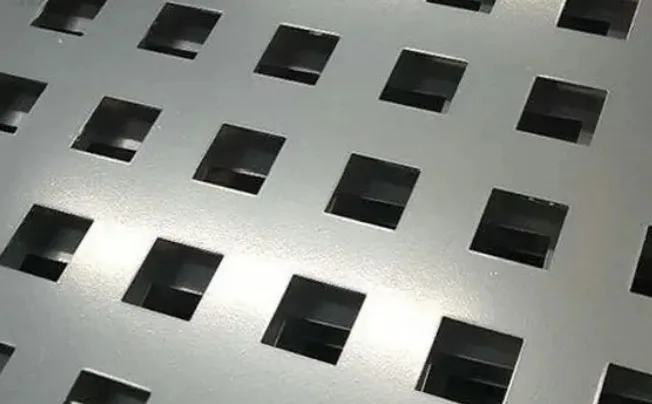

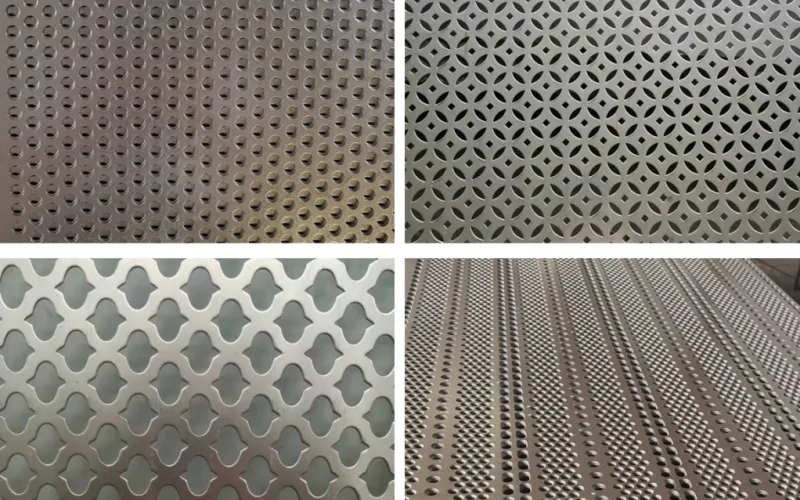

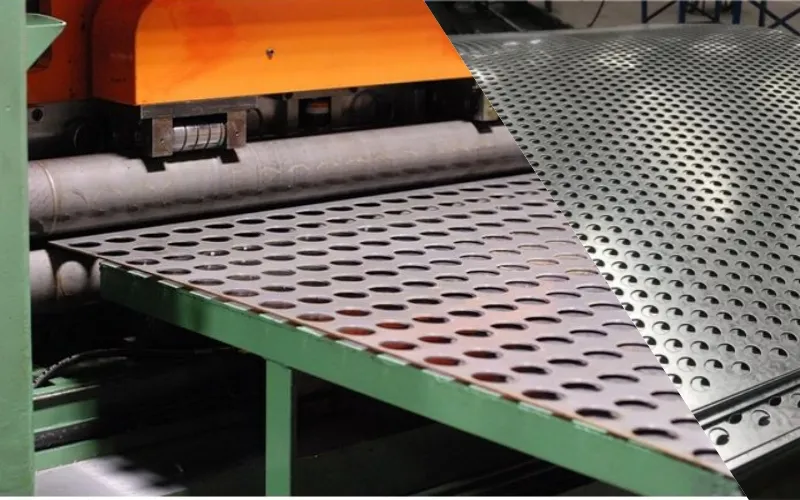

410 Stainless steel punching plate is a type of metal perforated sheet made from 410 stainless steel. The stainless steel plate will be punched by CNC punches according to a certain hole shape and mold. Also, the holes can be arranged in a regular or random pattern.

410 Stainless Steel

The 410 stainless steel grade is hardenable and martensitic stainless steel that contains a minimum of 11.5% chromium. This addition of chromium provides increased corrosion resistance in mildly corrosive environments and high strength and hardness. The 410 stainless steel can be heat treated to obtain a wide range of mechanical properties and is magnetic in all conditions.

410 Chemical Composition

| C | Si | Mn | S | P | Cr | Ni |

| ≤0.08 | ≤1.0 | ≤1.0 | ≤0.03 | ≤0.040 | 11.5~13.5 | 0.6 Max |

410 Stainless Steel Punching Plate Specifications

| Standards | JIS, AISI, ASTM, GB, DIN, EN |

| Raw Material | stainless steel plate |

| Grades | 410 |

| Thickness | 1 – 12 mm or according to the customer’s requirements |

| Width | 600 – 1500 mm or according to the customer’s requirements |

| Length | 800 – 3000 mm or according to the customer’s requirements |

| Hole size | 0.2 -155 mm or according to the customer’s requirements |

| Hole patterns | round, square, rectangular, slotted or elongated, hexagonal, triangle, geometric, micro-porous, diamond, irregular holes, or according to the customer’s requirements |

| Finish | 2B, 2D, BA, No 4., HL, 6K/8K, brushed, polished, etc |

| Punching arrangement methods | straight row (90 degrees straight ), staggered row (60 degrees staggered or 45 degrees staggered), irregular row, combination arrangement of large and small holes, etc |

| Value-added service | cutting, rolling, folding, welding, bending, etc., |

| Package | plastic film packing and pallet transportation, or according to the customer’s requirements |

410 Stainless Steel Punching Plate Properties

1. Corrosion Resistance

410 stainless steel has good corrosion resistance in mildly corrosive environments.

2. High Strength

Stainless steel material offers high strength and rigidity, which can withstand large pressure and tension and is not easy to deform and break.

3. Design Flexibility

At Gnee Steel, our stainless steel corrugated plates, including 410 stainless steel, are available in a wide variety of thicknesses, widths, lengths, finishes, hole patterns, and grades to choose from. Also, we support customization to meet specific design requirements.

4. Mechanical Strength

| Tensile Strength | Yield Strength | Elongation (%) | Hardness | Bending Angle |

| > 450 Mpa | > 205 Mpa | > 20% | <HRB96 | 180° |

5. Versatility

The perforation design provides a range of functional properties. For example, it can reduce weight and reduce the passage of light, liquid, sound, and air, which makes 410 stainless steel punched sheets widely helpful in various applications.

6. Magnetic Properties

410 stainless steel is magnetic in both the annealed and hardened conditions.

7. Beautiful Appearance

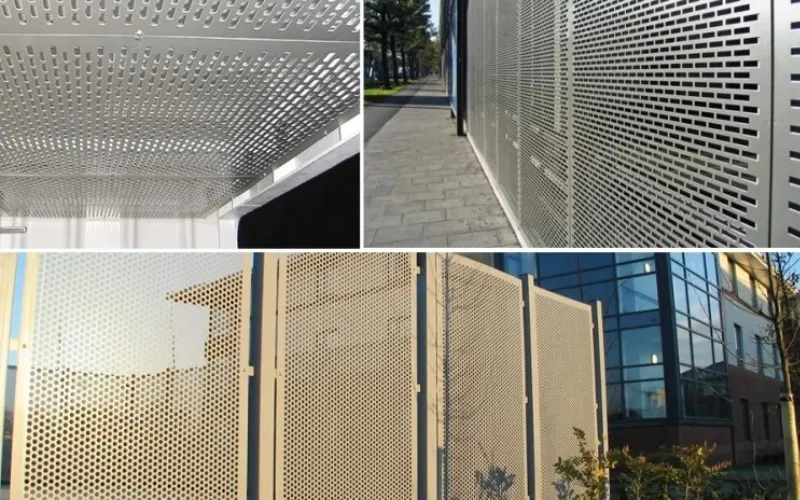

It also has good decorative properties and can be used in both exterior and interior decorations. Its sleek and modern look can add visual interest and texture, enhancing its overall aesthetic.

8. Easy to Maintain

The smooth surface of stainless steel makes it easy to clean and maintain, reducing the need for frequent cleaning and maintenance.

410 Stainless Steel Punching Plate Applications

The 410 stainless steel punching plate is commonly used in various applications, including:

1. Construction Structure

410 Stainless steel perforated plates are commonly used in ceilings, walls, platforms, stair handrails, protective railings, and other parts in the field of architectural decoration. On one hand, its unique hole structure allows air circulation and good light transmittances; on the other hand, the stainless steel perforated plate can provide good load-bearing capacity and compression resistance.

2. Industrial Filtration

Stainless steel punched plates are commonly used in filters, screens, and other equipment in the field of industrial filtration. 410 Stainless steel punched plates are corrosion-resistant, high-temperature resistant, and wear-resistant, and are suitable for filtration operations of various liquids and gases.

3. Auto Parts

Stainless steel punching plates are commonly used in seat brackets, door panels, radiators, engine hoods, and other parts to provide good ventilation and prevent impurities from entering.

4. Wall and Partition

They can be used as partitions or walls to divide space or create privacy areas.

5. Protecting and Fencing

They are often used in greenhouses or animal enclosures to provide a durable, corrosion-resistant, and easy-to-clean surface that allows ventilation and natural light to pass through.

6. Other Uses

410 Stainless steel punching plate can be used in manufacturing: handicrafts, high-end speaker grille, food processing machines, sound barriers, dust collectors, electronic instrument housing, etc.

410 Stainless Steel Perforated Plate Inspection Standards

Here are some things to note when inspecting 410 SS punching plates:

1. The hole diameter and spacing of the perforated stainless steel sheet must be evenly distributed across the entire plate, and there are certain rules for both horizontal and vertical tilts.

2. There are no through holes on the surface of the stainless steel perforated plate.

3. The thickness of the board must meet the standards.

4. The surface of the perforated stainless steel sheet should be smooth and clean.

5. The formed perforated stainless steel sheet must reach the level specified by the customer.

6. The deep processing of perforated stainless steel mesh should meet the shaping and coloring standards.

Gnee Steel is a professional manufacturer of stainless steel perforated plates, and we can provide different stainless steel perforated plate inspection standards if needed.