Product Introduction

310 Stainless steel clad plate, also known as 310 stainless clad steel plate, is a composite material made by bonding stainless steel plate (cladding material) to either or both sides of a carbon steel or low alloy steel plate (base metal). Bonding will form a diffusion layer between these two kinds of plates. That diffusion layer has a stable mechanical performance without obvious grain micro-structure, and its internal mechanical properties show a graded change in the thickness direction.

Moreover, this kind of plate unites the good weldability, ductility, and thermal conductivity of carbon steel and the high corrosion resistance, abrasion resistance, and magnetic resistance of stainless steel. Thus it features excellent cost-effectiveness when being applied in many different applications.

Grade 310 Stainless Steel

Grade 310 stainless steel is one of the most widely used grades of heat-resistant stainless steel. The key properties of this material are its high chromium and medium nickel content, making it have higher strength and better creep strength at elevated temperatures.

Grade 310 Stainless Steel Chemical Composition

| C | Mn | Si | P | S | Cr | Mo | Ni | N |

| ≤0.25 | ≤2.00 | ≤1.50 | ≤0.045 | ≤0.030 | 24.0-26.0 | – | 19.0-22.0 | – |

Grade 310 Stainless Steel Physical Properties

| Density, lb/in3 | 0.290 |

| Modulus of Elasticity, psi | 29.0 x 106 |

| Coefficient of Thermal Expansion, 68-212℉, /℉ | 8.8 x 10-6 |

| Thermal Conductivity, Btu/ft hr℉ | 8.0 |

| Specific Heat, Btu/lb ℉ | 0.12 |

| Electrical Resistivity, Microohm-in | 30.7 |

Grade 310 Stainless Steel Mechanical Properties

| Yield Strength 0.2% offset (KSI) | 30 min |

| Tensile Strength (KSI) | 75min |

| Elongation % | 40 min |

| Hardness (HV) | 225 max |

310 SS Clad Plate Specifications

| Raw Material | base metal: low alloy steel or carbon steel (Q235B、Q345R、Q355、Q245R、20#、40#…)

cladding metal: stainless steel (304, 304L, 310, 310S, 316, 321, 318, 410S, 420, 904L…) |

| Grade | 310 |

| Standard | ASTM, AISI, DIN, EN, GB, JIS |

| Thickness | base material thickness: 0.5 – 50 mm

cladding material thickness:0.5mm -20 mm |

| Width | 100 – 800 mm |

| Length | 500 – 15000 mm |

| Shape | rectangular, square, round or as required |

| Production Method | explosive cladding, hot/cold rolling |

| Surface | NO.1, 2B, BA, 4K, 8K, HL, NO.4, annealed, pickled, polished, |

| Value-added Services | plasma cutting, saw cutting, shearing, laser cutting, waterjet cutting, forming, welding, machining, leveling, rolling, bending, etc |

| Package | standard export seaworthy package or as required |

Note: The material and thickness can be freely combined to meet the needs of different users.

How Is the Plate Made?

The plate is readily fabricated by standard industrial procedures. Upon request, it is usually divided into explosion cladding and rolling cladding.

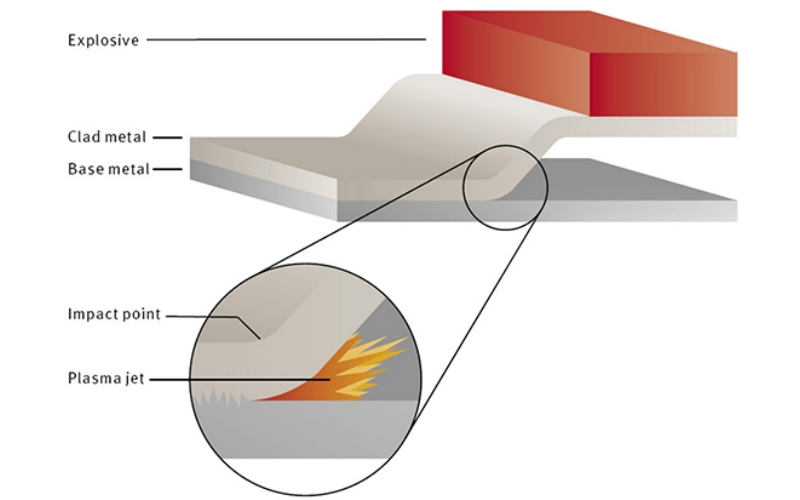

1. Explosion Cladding

This is how the explosion-bonded 310 SS clad plates are made. When the 310 stainless steel plate is superimposed on a carbon steel plate, the explosive will be laid on the surface of the stainless metal. Once bursting, the energy generated by the explosion makes the cladding material hit the base material at a very high speed. Meanwhile, the high temperature and high pressure prompts these two materials to be fused and welded together at the interface of two materials. Ideally, the shear strength per square millimeter of the interface can reach 400 MPa.

Compared with the traditional cladding method, explosive adhesion features a super high bonding strength and corrosion resistance, as well as improved mechanical and thermal performance. Meanwhile, explosion bonding technology can produce a clad plate with a total thickness of up to 200mm. What’s more, SS clad plates of round shape can only be produced by explosion bonding.

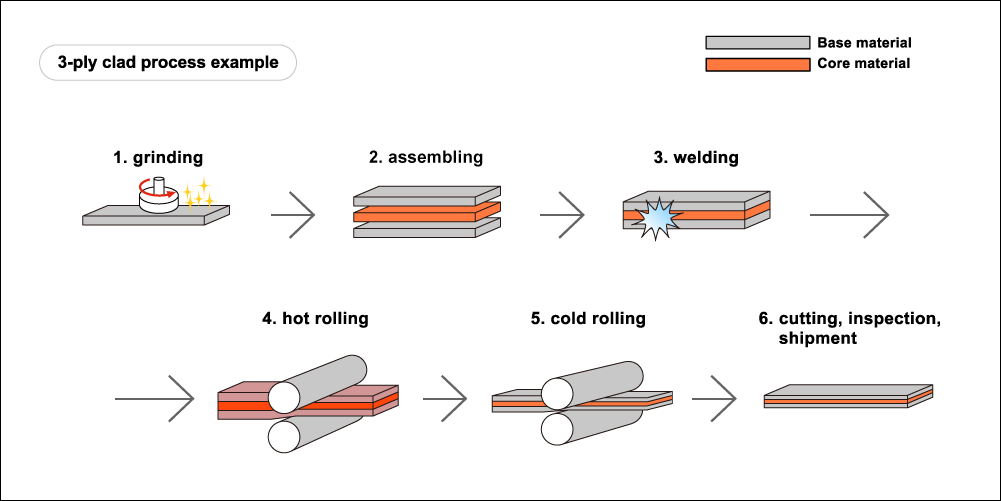

2. Rolling Cladding

Before the rolling process, the surfaces of stainless steel and carbon steel will be cleaned appropriately by a grinding machine to remove contaminants or an oxide layer. When rolling, it is often divided into hot rolling and cold rolling.

1. Hot Rolling

Hot rolled 310 stainless steel clad plate is made by the following steps: when the carbon steel substrate and stainless steel plate are in a physically pure state, the two plates will be rolled under high vacuum conditions. Firstly, the carbon steel will be stacked with stainless steel and the plate edges will be welded with four carbon steel seals. A hole will be drilled in the middle of one seal, and the air in the plate interface will be pumped out through the hole by a vacuum pump reaching a proper vacuum degree (0.5 P — 5 Pa). After being heated to a temperature of 1100℃ for 3h in a pit furnace, the plate was multiple-pass rolled at a temperature of 800℃ before being cooled in the air.

Hot rolled 310 stainless cladding plates are a leading-edge material. It ensures the features of low price, high strength, good corrosion resistance, oxidation resistance, wear resistance, and more than 50 years of service life.

2. Cold Rolling

Cold rolled 310 stainless steel clad plate is manufactured on the basis of hot rolled 310 stainless clad plate. When the hot rolled 310 stainless clad plate is cooled to room temperature, it will go through annealing, pickling, cold rolling, intermediate annealing, pickling (or bright annealing), tension leveling, and other production processes. The surface of cold rolled 310 stainless clad plate reaches the surface quality of the same series of stainless steel, and the yield strength is better than that of the same grade of stainless steel. With the thinnest thickness of 0.6mm, it is much more suitable for the civil field and decoration projects.

Why People can Trust it?

310 SS clad plate features strong points of carbon steel and stainless steel. It has numerous benefits you can enjoy:

1. Good Corrosion Resistance: the stainless steel material contains high chromium, which forms a protective oxide layer on the surface. It can provide strong resistance to various corrosive media, including acids, alkalis, moisture, rust, stains, and other environmental factors.

2. High-temperature Resistance: this sort of plate contains 25% chromium and 20% nickel, making it highly resistant to corrosion and oxidation to 2000°F. So it is an ideal choice for projects that require service at temperatures up to 1150 degree Celsius.

3. Good Processing Performance: due to a strong metallurgical bonding formed by carbon steel and stainless steel, it is very ductile and has good weldability, including hot pressing, cold bending, cutting, machining, and so on.

4. Light Weight: as a metal material, it is always has lightweight but high strength. What’s more, the thickness of cladding metal constitutes only 10–20 % that of the stainless steel clad plate.

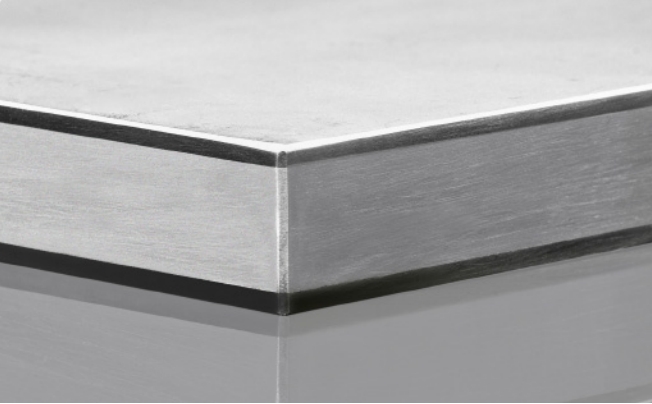

5. Flat & Smooth Surface: it possesses a smooth and non-porous surface, making it easy to clean and maintain hygiene standards and highly suitable for industries with stringent cleanliness requirements.

6. Cost-effective Solution: it is a resource-saving material. Compared with pure stainless steel plates, the stainless steel clad plates can reduce alloy elements like Cr and Ni by 70–80 % and reduce costs by 30–50 % because of the low cost of carbon steel. It realizes the perfect combination of low cost and high performance, having good social and economic benefits.

Applied Fields

These clad plates are designed to improve corrosion/heat resistance while retaining low cost, high strength, and light weight. It can be used above 1000 degrees Celsius in continuous applications and above 1150 degrees Celsius in intermittent services. In view of that, the industries it involves include:

1. Construction and Infrastructure

It is a perfect building material that can guarantee a longer lifespan due to the low thermal expansion rate, high strength, and high rust resistance. It can be utilized in bridges, tunnels, structural components, building facades, walking beams, panels, doors, windows, fans, roofing, shipbuilding, curtain wall of high-grade building, offshore platforms, steel structures, etc.

2. Automobile Industry

It can be found in automobiles, trains, aircraft, and ships for various components. They include exhaust systems, automotive frames, vehicle and ship luggage racks, flue gas desulfurization systems, body components, engine parts, structural parts, interior fittings, etc.

3. Food Processing

It is known that 310 stainless steel is food-grade stainless steel, hence it has non-reactive nature, ease of cleaning, and corrosion resistance. Generally, it is used for the manufacturing of various food processing equipment, such as storage containers, kitchen wares, home appliances, and so on.

4. Medical and Healthcare

Due to its sterilizability, biocompatibility, low magnetic permeability, and corrosion resistance, the plate is commonly used in medical equipment, structural components for cryogenic vessels, surgical instruments, cleanrooms, implants, and so on.

5. Manufacturing Industry

It is used to manufacture 310 stainless steel coils, pipes, profiles, and fittings. Besides, it can be used in making smelter and steel melting equipment, continuous casting equipment, annealing covers and boxes, burners, tube hangers, various processing plants, and so on.

6. Coal & Energy Industry

It is largely founded in transportation pipelines, storage tanks, refineries chemical containers, power plants, equipment exposed to harsh chemicals, nuclear facilities, and renewable energy sectors.

7. Industry

It is used to make pressure vessels, pagodas, conveyor systems, pumps, water treatment plants, steam boilers, pulp and paper equipment, lead pots, burners, muffles, saggers, and other industrial equipment.

8. Public Uses

It can also be used to fabricate electronics, promotional signage racks, poles, advertising columns, fitness equipment, furniture, platform barriers, roadblocks, isolation belts, expansion joints, wind boxes, and other interior and exterior decorations.

However, it should be noted that ASTM 310 stainless steel clad plate is not recommended for being used in a wet corrosive environment. Its increased carbon content to enhance creep properties adversely affects its water corrosion resistance.

Prominent 310 SS Clad Plate Manufacturer

In a word, 310 stainless steel clad plate combines the characteristics of carbon steel and stainless steel, warmly welcomed by users for its excellent performance and favorable price, having broad market prospects. We, Gnee Steel, offer stainless steel clad plates in 310, 316, and 347 grades with excellent bonding quality and reliable performance. And they are also in various sizes and finishes at the best price to help you to prove one of the best stockholder 310 SS cladding plates in China.