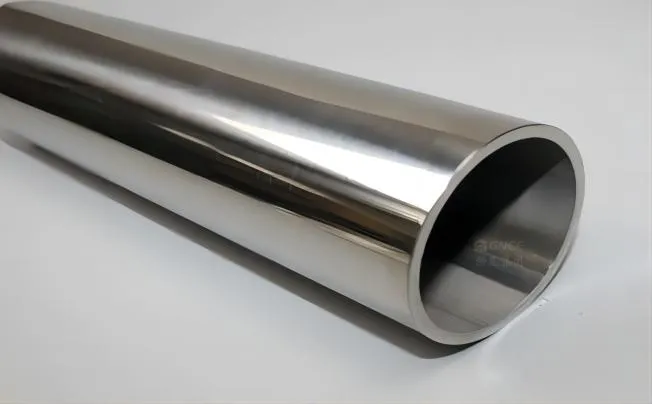

What are Stainless Steel Welded Pipes?

A pipe made of stainless steel that has been longitudinally welded is created by rolling a stainless steel strip or plate into a tube shape. It is frequently utilized in sectors that need improved corrosion resistance and high-temperature strength. Several techniques, including resistance welding (ERW), submerged arc welding (SAW), high-frequency induction welding (HFIW), etc., can be used to complete the welding process. It can also be subjected to additional processing using cold rolling and forging techniques to create seams, welds, and surfaces with finer finishes and tighter tolerances.

What are the Advantages of Stainless Steel Welded Pipe?

Strength: Welded joints are inherently strong and can withstand high pressure and stress.

Seamless Appearance: The weld seam can be smoothed or ground to create a seamless appearance.

Cost-Effective: Welded pipes are generally more cost-effective than seamless pipes.

Availability: Welded pipes are readily available in a wide range of sizes and lengths.

Commonly Used Models: 304, 309S, 310S, 316L

With welded pipes, there are a few things to think about:

Weld Seam: Although contemporary welding procedures have greatly increased the strength and integrity of welded connections, the presence of a weld seam may still result in a weak spot in the pipe.

Resistance to Corrosion: The weld seam may be more prone to corrosion than the rest of the pipe. Effective surface preparation and coating can lessen this problem.

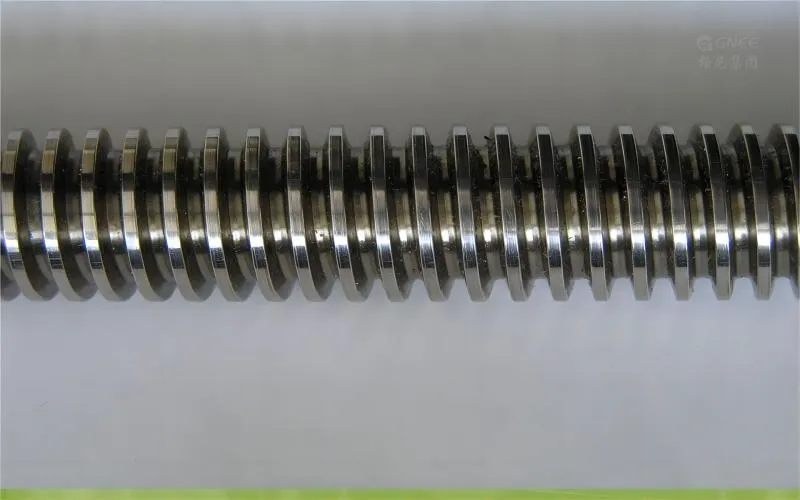

What are Stainless Steel Threaded Pipes?

A stainless steel pipe with threads on the end that can be screwed into fittings or other pipes is known as a stainless steel threaded pipe. British Standard Pipe (BSP) threads, a common form of thread used in pipes and ductwork, are often the threads on pipes. They are frequently used in ducting, industrial plumbing, and other applications where corrosion resistance and longevity are vital since they are simple to install and remove for maintenance and repair.

Stainless steel threaded pipe is available in a variety of stainless steel grades, including 304 and 316, which offer the advantages of stainless steel, such as corrosion resistance and durability, while also supplying a safe and leak-proof connection.

What are the Types of Threaded Pipes?

- Taper Pipe Thread

The most typical type of pipe thread in a variety of industries is tapered. When you twist the pipes together, these conical threads tighten, forming a tight seal. National Pipe Threads (NPT) is a widely used tapered pipe thread standard that is suited for conveying liquids or gases under pressure. They have a 60-degree angle, rounded peaks and valleys, and a tight seal without the need for gaskets.

- Straight Pipe Thread

Because the cylindrical shape of straight pipe threads prevents them from creating a tight seal, joints must be sealed with a gasket or O-ring. The Uniform Thread Standard (UTS), which is frequently used in the US and Europe for pipes carrying non-pressurized fluids like drain pipes, is a well-known straight pipe thread standard.

- API line Pipe Thread

The oil and gas industry frequently uses tapered, rounded peaks and valleys, 30-degree thread angles, and tapered API line pipe threads to resist high pressures and temperatures. Thread grease is needed to lubricate and improve the seal on API line pipe threads, which makes them unsuitable for low-pressure fluid and gas applications.

- Partial Trapezoidal Thread

Partial trapezoidal threads, which are frequently used in pipes bearing severe loads and high pressures, such as those used in hydraulic systems, are distinguished by sloping flats on both sides of the line. Serrated threads come in internal and exterior varieties. In contrast to internal trapezoidal threads, external trapezoidal threads are flat on the inside of the line. Offset threads produce a tight seal, but lubrication is necessary to keep them from breaking.

- Square Thread

A special kind of straight pipe thread with a rectangular shape is called a square thread. Because of their exceptional strength, these threads are frequently employed in lead screws and other high-power transmission devices. Although these threads need more precise machining than other thread kinds, they tend to wear less than other thread types.

What are the Advantages of Stainless Steel Threaded Pipe?

Easy Installation: Threaded connections are excellent for applications that need periodic maintenance or alterations since they are reasonably simple to build and remove.

Versatility: Threaded pipes have a wide range of fittings they can simply connect to, giving system designers flexibility.

Threaded pipes reduce installation costs by removing the requirement for welding knowledge and equipment.

With threaded pipes, there are a few things to think about:

Lower Pressure Rating: Compared to welded joints, threaded connections may have a lower pressure rating, which makes them less appropriate for high-pressure applications.

Potential Leakage: Threaded connections that are improperly installed or tightened run the risk of developing leaks.

Limited diameters: Threaded pipes are normally only available in smaller diameters, and joining methods for higher-diameter pipes may differ.

Choose Stainless Steel Threaded Pipes or Stainless Steel Welded Pipes

The individual application, operating circumstances, and project needs are only a few of the variables that influence whether to use welded or threaded pipe. Here are some things to think about:

Temperature and Pressure: Welded pipe may be a better option if the system works at high pressure or temperature due to its inherent strength and leak resistance.

Upkeep and Modifications: A threaded pipe may be more practical if the system needs frequent maintenance or alterations because it is simple to put together and take apart.

Pipe Size: Threaded pipe is frequently utilized for smaller pipe diameters. However, due to its greater strength and pressure rating, welded pipe is frequently favored for bigger diameters.

To determine the precise needs of an LPG station design and make workable solutions based on variables like pressure, temperature, pipe sizing, and maintenance considerations, you can speak with a certified engineer or plumbing specialist.