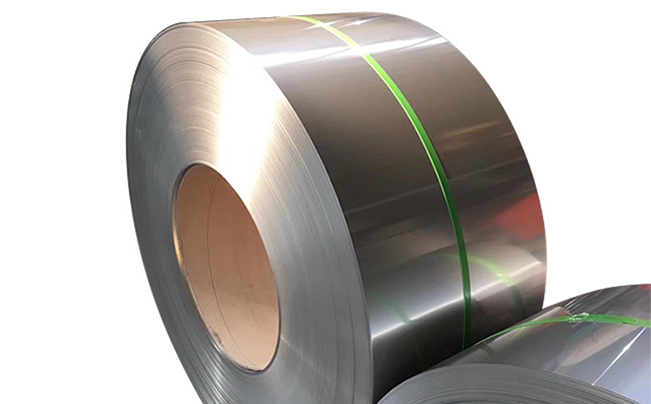

What Is 430 Stainless Steel Coil?

430 stainless steel coil is a coiled product made of 430 stainless steel. It is an iron-chromium alloy stainless steel with a chromium content of 16%-18%. Compared with 304 stainless steel and 316 stainless steel, the chromium content is lower, so it is slightly inferior in corrosion resistance and strength. However, 430 stainless steel coils have the advantages of excellent heat resistance and magnetic properties, as well as relatively affordable prices, and are widely used in some occasions that require medium strength and corrosion resistance, such as home appliance manufacturing and other industries.

Product Details

| Product Name | 430 stainless steel coil |

| Grades | 430/EN 1.4016/SUS430 |

| Hardness | ≤200HV |

| Thickness | 0.02mm-6.0mm |

| Width | 1.0mm-1500mm |

| Quantity Tolerance | ±10% |

| Surface Finish | NO.1/2B/2D/BA/HL/Brushed/6K/8K Mirror,etc |

| Packaging | Wooden Pallet/Wooden Case |

| Delivery Time | 5-7 working days |

| Sample | The sample of 430 stainless steel coils is available |

Classification of 430 Stainless Steel Coils

The two common types of 430 stainless steel coils are cold-rolled stainless steel coils and hot-rolled stainless steel coils. Cold-rolled stainless steel coils have the characteristics of better surface quality, higher hardness, higher dimensional accuracy, and strong rust resistance; while hot-rolled stainless steel coils have higher production efficiency and heat resistance. The choice of which processing technology to use depends on the use environment and requirements. Let’s take a look at the differences between them.

| 430 Stainless Steel Coil | Type | Introduce | Features |

| Cold Rolled Stainless Steel Coil | Cold-rolled stainless steel coils are processed by cold-rolling stainless steel slabs at room temperature, and the stainless steel slabs are gradually cold-pressed and thinned by rolling mills to make them into the required thin plates. | Good surface smoothness | |

| Higher hardness | |||

| High dimensional accuracy | |||

| Strong anti-rust ability | |||

| Hot Rolled Stainless Steel Coil | Hot-rolled stainless steel coils are made by heating stainless steel slabs to high temperatures and then rolling them. It is carried out at high temperatures and rolled by rolling mills to form the required thickness. | High productivity | |

| Strong heat resistance | |||

| Relatively low dimensional accuracy | |||

| Relatively poor surface quality |

The Difference between 430 Stainless Steel Coil and 409、410、420 Stainless Steel Coil

430 Stainless Steel Coil, 409 Stainless Steel Coil, 410 Stainless Steel Coil, and 420 Stainless Steel Coil These 400 series stainless steel coils have obvious differences in chemical composition and characteristics. Let’s take a closer look at it.

430 stainless steel is an iron-chromium alloy stainless steel. Its main features are heat resistance and magnetism, but it is slightly inferior to other stainless steels in terms of corrosion resistance and strength. It is widely used in scenarios that require high heat resistance and magnetism.

409 stainless steel is usually used for corrosion-resistant parts working at high temperatures. It has low chromium content but has high aluminum and titanium content, and its oxidation resistance and corrosion resistance are greatly improved.

410 stainless steel is a kind of stainless steel with high hardness and wear resistance, which is usually used in the manufacture of high-strength occasions such as knives and bearings.

420 stainless steel is a high-carbon chromium stainless steel, which is often used in the manufacture of products with high hardness and wear resistance, such as knives, needle bars, and valves.

The above four types of stainless steel coils are some of our best-selling 400 series stainless steel coils. They have their characteristics and are suitable for different application scenarios. If you have needs in this area or have any questions about it, please feel free to contact us. We will help you conduct professional analysis and provide suitable products according to your specific needs.

What Is 430 Stainless Steel Curling?

Stainless steel hemming refers to the portion of the edge of the coil, including the edge produced during cutting, leveling, and handling. It is usually classified as hard edge and round edge, depending on the production process and processing method.

When using stainless steel coils, the treatment of curling is also very important. Stainless steel crimping can be done by cutting, bending, etc. so that it can be well combined with other materials or processed parts. During the forming process of stainless steel, the curling also needs to be polished and polished to ensure that the shape and surface quality meet the requirements.

The treatment of curling directly affects the use effect of stainless steel coils. Every process in the manufacturing process of stainless steel coils is an important factor in determining product quality. Every process of stainless steel manufacturing in Gnee’s factories strictly controls the quality to ensure the quality of the products, and never let inferior products flow into the hands of our customers.

Features of 430 Stainless Steel Coil

430 stainless steel coil is a widely used type of stainless steel coil, its characteristics are as follows:

- Good heat resistance

- Has a certain degree of magnetism

- Good processing performance, easy to process into various shapes

- Low chromium content, poor corrosion resistance, but still has good corrosion resistance in a dry environment

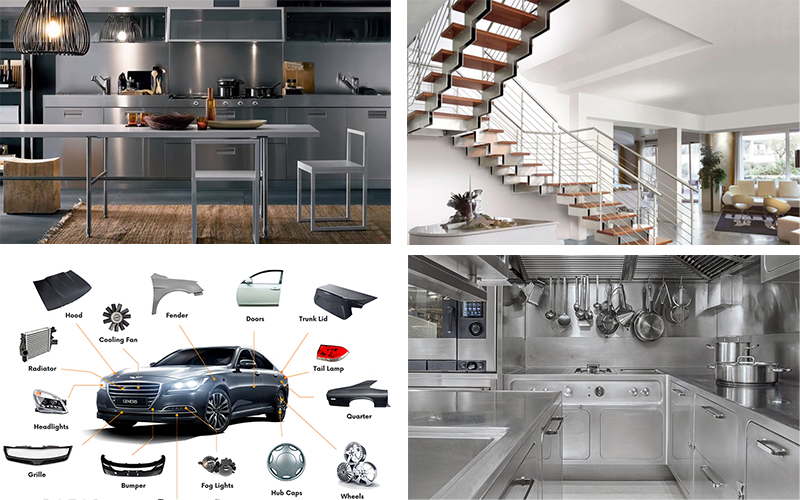

Application Scenarios of 430 Stainless Steel Coil

430 stainless steel coils can be used in a variety of application scenarios due to their special physical and chemical properties. Let’s take a look.

Kitchen Equipment: 430 stainless steel coils can not only resist the corrosion of food acid and alkali, but also have good high-temperature resistance, and are widely used in the manufacture of kitchen equipment. Equipment such as stoves, ovens, microwave ovens, range hoods, etc. usually uses 430 stainless steel coils as the shell material.

Architectural Decoration: 430 stainless steel coil has become a popular decorative material due to its excellent surface finish and weather resistance and is widely used in the field of architectural decoration. Such as door and window frames, handrails, cabinet doors, balcony railings, etc.

Auto Parts: 430 stainless steel coils are also widely used in the automotive manufacturing industry and are often used to manufacture exhaust systems, automotive drain pipes, hoods, and body parts to meet the automotive industry’s requirements for durability and reliability.

Furniture Manufacturing: In the field of furniture manufacturing, 430 stainless steel coils are often used to make furniture frames, chair legs, bed frames, etc. Stainless steel furniture has many advantages such as durability, easy cleaning, and corrosion resistance, and it also adds a modern and high-end quality to the furniture.

Due to its excellent performance, 430 stainless steel coil plays an important role in many industries such as kitchen equipment, architectural decoration, automobile manufacturing, furniture manufacturing, etc. It is a stainless steel material with a wide range of uses. If you have needs in this area, please feel free to contact us, we will provide you with the most professional advice, the most suitable products, and the best service!

High-Quality Stainless Steel Coils Supplier

The Gnee Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gnee Steel Group, you choose a professional and reliable steel supply chain partner!