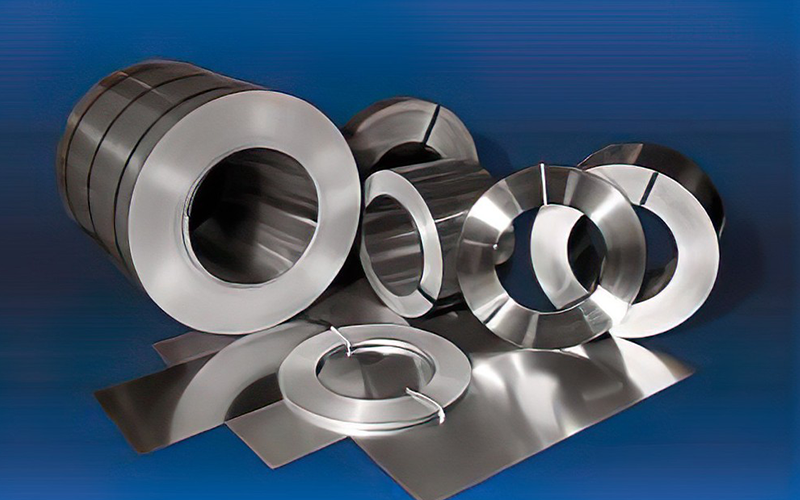

What Is 2507 Stainless Steel Coil?

2507 stainless steel coil refers to the stainless steel coil made of 2507 duplex stainless steel, also known as SAF 2507. This stainless steel is a combination of austenitic and ferritic stainless steels with high levels of chromium, molybdenum, and nitrogen. Due to the duplex structure, the 2507 stainless steel coil has more advantages than other types of stainless steel. Commonly used in oil, gas, chemical processing, pulp production, and other industries requiring high corrosion resistance and mechanical strength.

Product Specification

| Thickness Range | 1.2mm-10mm |

| Width Range | 600mm-2000mm, please refer to strip products for narrow products |

| Maximum Coil Weight | 40MT |

| Coil Inner Diameter | 508mm, 610mm |

| Surface Treatment | NO.1, 1D, 2D, #1, hot rolling surface treatment, blackening, annealing and pickling, rolling surface treatment |

Chemical Composition

| Element | C | Si | Mn | Cr | Ni | S | P | Mo | Cu | N |

| Chemical Composition | ≤0.03 | ≤0.8 | ≤2.0 | 24.0~26.0 | 6.0~8.0 | ≤0.02 | ≤0.035 | 3.0~5.0 | < 0.5 | 0.24~0.35 |

Mechanical Behavior

| Mechanical Behavior | tensile strength | Yield Strength | Elongation(%) | hardness |

| Value | > 795MPa | > 550MPa | > 15% | < HV310 |

2507 Hot Rolled Stainless Steel Coil

2507 hot-rolled stainless steel coil is a stainless steel material rolled at high temperature. Made of 2507 duplex stainless steel, a high strength, corrosion resistant alloy. Hot rolling is a manufacturing process in which stainless steel is heated above its recrystallization temperature, then passed through a series of rolls to reduce its thickness and form into coils. Improves the mechanical properties of stainless steel, including strength and toughness.

201 stainless steel hot-rolled plates, 430 stainless steel hot-rolled plates, 304 stainless steel hot-rolled pipes, etc. are also used in the hot-rolled process. Gnee Steel is a high-quality stainless steel coil supplier, selling various types of stainless steel products, welcome to contact us.

The Difference between 2507 and 2205 Stainless Steel Coil

Both 2507 stainless steel and 2205 stainless steel are duplex stainless steel materials with similar structures, but there are still some differences between them, let us find out together.

The main components of 2507 stainless steel include chromium, nickel, molybdenum, and copper, and its chemical composition is higher than that of 2205 stainless steel. And in an environment with high chloride ion content or high-temperature conditions, the corrosion resistance of 2507 stainless steel is better than that of 2205 stainless steel. In addition, 2507 stainless steel has higher strength and wear resistance than 2205 stainless steel, so the price of 2507 stainless steel coil is generally higher than that of 2205 stainless steel coil.

Which material to choose should be determined according to the specific use environment and requirements to balance the performance and cost of the material. Choose Gnee, professional technicians will give you the best product solution.

Advantages of 2507 Stainless Steel Coil

The special structure of 2507 stainless steel coil brings it many advantages:

Good corrosion resistance: 2507 stainless steel coil has excellent corrosion resistance and can resist a variety of corrosive media, including acids, alkalis, salts, etc. At the same time, it can resist stress corrosion cracking and intergranular corrosion and is suitable for use in harsh environments.

Excellent mechanical properties: Due to the dual-phase structure, 2507 stainless steel coils have high yield strength, tensile strength, and impact toughness, and can maintain good mechanical properties under high and low-temperature conditions.

Superior welding performance: 2507 stainless steel coils have good welding performance and can be welded without affecting the material properties. Conventional welding methods can be used, such as arc welding, inert gas-shielded welding, etc.

Excellent processing performance: 2507 stainless steel coil has good plasticity and forge ability, is easy to process into products of various shapes and sizes, and is suitable for complex processing techniques.

2507 stainless steel coil is a high-performance material with excellent corrosion resistance, mechanical properties, easy welding, and processing, and is suitable for various harsh industrial and construction fields.

Application Field of 2507 Stainless Steel Coil

Oil and Gas Industry: 2507 stainless steel coils are used to manufacture oil and gas extraction, storage, and transportation equipment, such as pipelines, storage tanks, valves, etc.

Chemical Industry: 2507 stainless steel coils can withstand harsh conditions such as strong acid, strong alkali, and high temperature, and are widely used in chemical equipment manufacturing, such as reactors, heat exchangers, storage tanks, containers, pipelines, etc.

Ocean Engineering: Due to its excellent corrosion resistance and high strength characteristics, 2507 stainless steel coils are widely used in the field of ocean engineering, such as manufacturing offshore platforms, submarine pipelines, ships, seawater desalination plants, high-pressure reverse osmosis equipment, etc.

Medical Industry: 2507 stainless steel coil has good biocompatibility and corrosion resistance and is widely used in the manufacture of medical equipment, such as surgical instruments, implants, etc.

Construction and Structure Fields: 2507 stainless steel coils are widely used in building facades, roofs, bridges, and other structures, which can provide long service life and a good appearance.

Paper and Fiber Industry: The high corrosion resistance and high strength of 2507 stainless steel coils can be applied to various equipment in the paper and fiber production process, such as steam generators, storage tanks, conveyors, etc.

In addition to the above fields, 2507 stainless steel coils are also widely used in energy, automobile manufacturing, aerospace, and other fields. The selection of materials needs to be based on the specific use environment and requirements, please feel free to consult us for more detailed information.

2205 Stainless Steel Coil Manufacturer, Supplier, and Exporter

The Gnee Steel Group is a professional supply chain enterprise, mainly engaged in steel plate, coil, profile, and outdoor landscape design and processing. After 15 years of development, it has become a leading international steel supply chain company in the Central Plains. Relying on many iron and steel enterprises such as Angang Steel, we have a wide variety of products, including shipbuilding plates, pressure vessel plates, bridge decks, etc. We also provide pipes, bars, engineering design and manufacturing, and comprehensive stainless steel solution services. Cooperating with more than 600 companies around the world, the annual export capacity exceeds 80,000 metric tons. Choose Gnee Steel Group, you choose a professional and reliable steel supply chain partner!