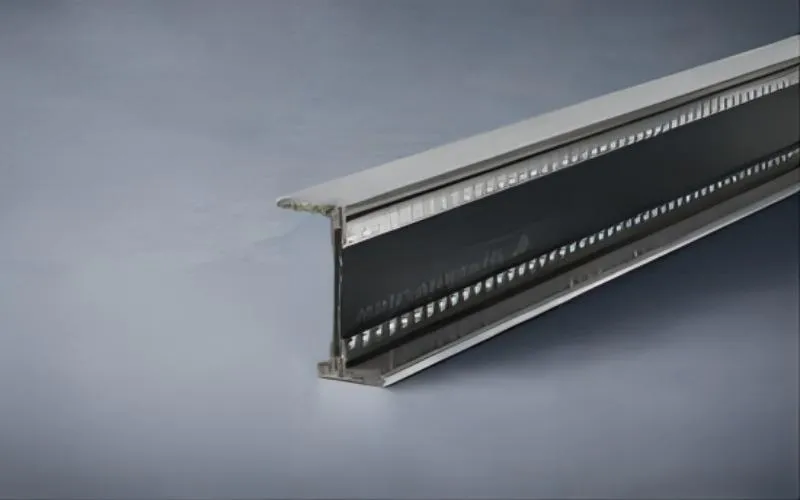

What is 420 stainless H-type steel?

420 stainless steel H-beam describes a particular grade of 420 stainless steel.

Chemical Composition: Grade 420 stainless steel has a strong level of corrosion resistance due to its average 12% chromium content. It can withstand corrosive media such as petrol, crude oil, steam, fresh water, weak alkalis, and disinfection solutions. Nevertheless, compared to stainless steels with higher chromium and nickel contents, it might not be as appropriate for extremely corrosive or harsh environments.

Its remarkable strength and hardness are also attributed to its less than 0.15% carbon content. With a 12% chromium content, it has the greatest hardness value of 50 HRC among stainless steel grades. Smaller amounts of silicon, phosphorus, sulfur, manganese, and silicon are also present.

Shear blades, dinnerware, surgical instruments, bearings, needle valves, bushings, screens, pump shafts, stairs, valve components, hand tools, etc. are among the common uses for 420 stainless steel.

Which type of stainless steel—304 or 420—is safer?

The stainless steels 304 and 420 each have special qualities and uses. It’s crucial to remember, nevertheless, that stainless steel is generally regarded as safe for use in everyday applications. Stainless steel’s safety is mostly determined by its composition, surface quality, and intended application.

Nickel adds to the corrosion resistance of austenitic stainless steel, such as 304 stainless steel. It is frequently utilized in many different applications, such as medical gadgets, household appliances, and equipment for preparing food. 304 stainless steel is more corrosion-resistant than other stainless steel grades like 420 because of its nickel content.

Pre-hardened steel with outstanding wear resistance and processability is called 420. It is frequently employed in the production of medium-sized extrusion and injection molds. Sulphur and phosphorus are two of the 420 impurity elements. Overconsumption will weaken 420’s ductility and hardness and make it more prone to flaws like pores and cracks.

The martensitic stainless steel known as 420 has a high hardness, a certain level of wear resistance, and resistance to corrosion. It is appropriate for many kinds of domestic appliances, transportation tools, electrical equipment, instruments, metres, and precision manufacturing. It is primarily utilized in the production of parts that are resistant to corrosion from oxidizing acids, steam, water, and the atmosphere.

Although 420 steel is of inferior quality, it can still be used for most things. Because of its comparatively low carbon content, it works well with softer blades. The edges have a tendency to dull when compared to premium steel.

What uses of 420 stainless H-type steel?

Grade 420 stainless H-type steel is used in many different industries because of its special set of qualities. These are a few typical applications for 420 stainless H-type steel:

Cutlery: Grade 420 stainless steel’s excellent hardness, resistance to corrosion, and sharpening qualities make it a popular material for making knives, cutlery, and blades.

Surgical devices: Because 420 stainless steel is robust, corrosion-resistant, and sterilizable, it is used in the manufacture of surgical instruments.

Industrial components: This kind of stainless steel is appropriate for a range of industrial components that need to be strong, resilient to corrosion, and wear-resistant. Cutting tools, blades, scissors, and other industrial equipment can all be made using it.

Food processing equipment: Because grade 420 stainless steel resists corrosion and can endure exposure to surroundings linked to food, it is utilized in the construction of food processing equipment.

Dental devices: Because of its hardness, resistance to corrosion, and sterilization properties, 420 stainless steel is frequently used in the production of dental instruments.

Pump shafts: 420 stainless steel can endure the harsh circumstances of fluid handling in pump shafts because of its high strength and resistance to corrosion.

its high strength and resistance to corrosion.

Polymer dies and molds: 420 stainless steel’s exceptional hardness and wear resistance make it a useful material for plastic molds and dies.

Ball bearings: Because of its great strength and resistance to corrosion, this kind of stainless steel can be utilized in the production of ball bearings.

Automobile parts: Grade 420 stainless steel is used in a variety of parts for automobiles that need to be strong and resistant to corrosion, like pivots, cams, and gear shafts.