What number of materials does 304 stainless steel consist of?

A common type of stainless steel with many uses and unique qualities is 304 stainless steel. 304 stainless steel is composed of multiple different materials. I’ll introduce you to a few common materials below.

304L stainless steel

A low-carbon variation of 304 stainless steel is called 304L stainless steel. Its chemical makeup is comparable to that of 304 stainless steel, but it has less carbon, which enhances corrosion resistance and welding performance. Equipment used in the food processing and chemical industries that requires welding can be made of 304L stainless steel.

304H stainless steel

This is 304 stainless steel with an increased carbon content. Increased carbon content can strengthen the material’s resilience to high temperatures, making it appropriate for use in furnaces and other high-temperature applications.

304LN stainless steel

Nitrogen has been added to 304 stainless steel to create 304LN stainless steel, which is a better material. Nitrogen addition can strengthen and resist corrosion, enabling the material to function better in specific unique situations.

Apart from the commonly used 304 stainless steel materials previously mentioned, there are additional variations and upgraded models available, including 304DDQ (deep drawing stainless steel), 304M (improved corrosion resistance), and 304HCU (high temperature resistance and corrosion resistance). The chemical make-up, physical characteristics, and potential applications of these various materials may vary.

Generally speaking, 304 stainless steel comes in a range of forms. In real-world applications, an appropriate 304 stainless steel material can be chosen to match the needs based on particular requirements and situations.

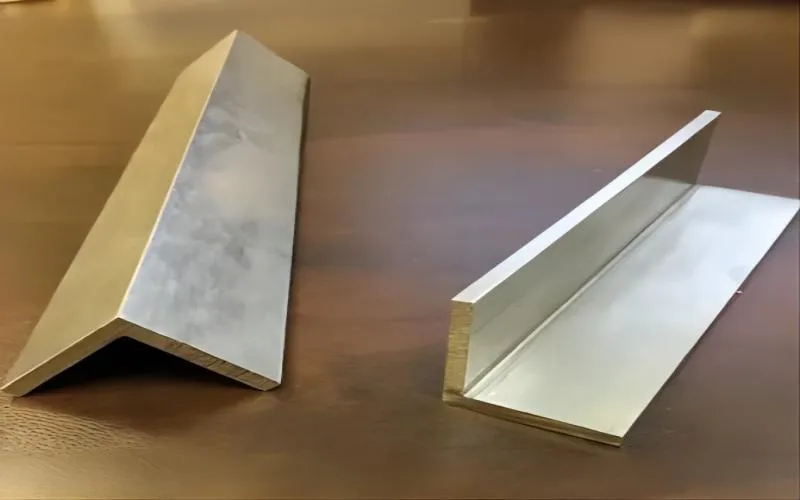

What is stainless angle steel?

angle of stainless steel Steel is a structural profile composed of stainless steel, sometimes referred to as stainless steel angle steel. Angles made of stainless steel come in several grades, including 304 and 316L. There are several sizes and profiles available to meet the needs of a given project.

How to identify 304 stainless steel?

1.Experimental research: Spectroscopy is usually a useful tool for component analysis.

2. Industrial: Soaking it in chemical agents allows you to identify it. There are numerous types of accessible solutions.

Using the pickling passivation solution for stainless steel as an example: (For example, SUS300 series (301/302/303/304…321): Following soaking, it will eventually take on a matte colour that is either the original natural colour or the mirror colour, and it won’t change colour again after that.

SUS200 series (201/202/203/204…): After soaking, the product will turn quickly black. You will rinse and contact the blackened product with your hands. The dark film is able to be ignited. The lotion will appear matte if you rub it across your face. pale hue. Should you persist in submerging it, it will corrode and the product will emit visible smoke.

SUS400 series of bubble martensitic stainless steel (410/420/430/440…): The product functions similarly to the SUS200 series after soaking. The sole distinction is that the black film needs to be soaked in a specific potion in order to be removed because it is essentially irreversible.

3. The easiest and most efficient way is the home screening technique, which involves using a magnet to draw in the target. Since SUS304 is not magnetic, it cannot be sucked up. The magnet is able to sense a modest suction force from the SUS200 series. Small goods will be consumed. Similar to iron, the SUS400 series sucks extremely tightly (this technique is most frequently employed for shrinking). There will always be a magnet with those who are useless.

For instance, a thermos cup made of stainless steel has the stamp SUS304 inside. You won’t experience any feelings if you use a magnet to draw it in. 304 is the number that has to be entered. The magnet is probably composed of 201 material if it can be lifted even a little. Long periods of time should not be spent using this type of cup. Heavy metals like manganese, lead, and chromium will precipitate under specific circumstances. It really is a poisoned cup. It is stainless iron if the magnet is really strong. This type of cup is especially prone to rusting. Stainless steel is mostly used to create blades; it is not appropriate for use in items like pots, pans, or cups.

Applications of 304 Stainless Angle Steel

- Sinks and splashbacks: Because of its resistance to corrosion and hygienic qualities, 304 stainless angle steel is frequently used in the production of sinks and splashbacks.

- Saucepans: 304 stainless angle steel is a good material to use for making saucepans because of its good mechanical qualities and resistance to corrosion.

- Cutlery and cutlery: Because 304 stainless angle steel resists corrosion and is long-lasting, it is utilized in the manufacture of cutlery and cutlery.

- Architectural panelling: Because of its attractive appearance and ability to withstand corrosion, 304 stainless angle steel is used in architectural panelling.

- Sanitaryware and troughs: Because of its hygienic qualities and resistance to corrosion, 304 stainless angle steel is frequently used in the production of sanitaryware and troughs.

- Tubing: 304 stainless angle steel is used to make tubing, which is employed in industry and architecture among other things.

- Equipment for the manufacture of beer, dairy, food, and pharmaceuticals: Because of its resistance to corrosion and hygienic qualities, 304 stainless angle steel is frequently used in the manufacturing of equipment for these industries.

- Springs, nuts, bolts, and screws: Because of its excellent mechanical qualities and resistance to corrosion, 304 stainless angle steel is utilized in the manufacture of springs, nuts, bolts, and screws.