How Do You Use a Pipe Cutter?

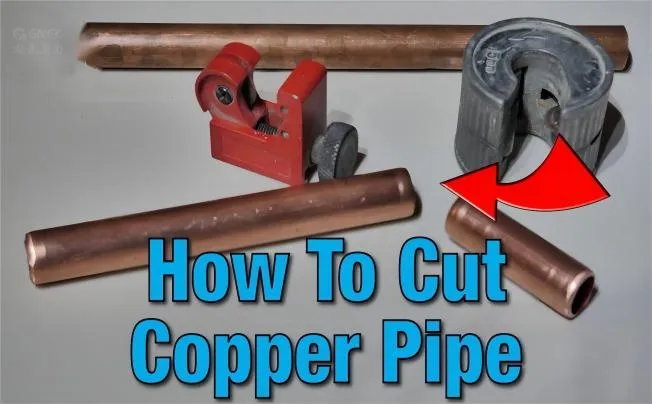

1. Fit the tubing cutter onto the pipe securely. To release the tubing cutter’s jaws, turn the handle. Wherever you want to cut, place the copper pipe into the jaws. Tighten the jaws tightly against the pipe by rotating the handle.

2. The tubing cutter acts like a vice to hold the pipe to the blade that’s in the tool.

3. Lightly score the pipe. Rotate the handle around the pipe once or twice with your other hand while holding the pipe in one hand. The faint line formed by the blade’s small incision into the pipe should be visible. You’ll use this line as a reference when you cut into the pipe.

4. Tighten and rotate the blade. To ensure that the blade keeps cutting into the pipe, keep turning the tool’s handle around it. Make sure the blade is cutting into the same line and not spiralling down the pipe by keeping an eye on it. As you proceed, tighten the cutter using the little knob on the tool’s base. This will maintain the blade’s trajectory.

5. Take out the cutter and remove the pipe. Take off and loosen the tubing cutter. With the incision in the middle, you ought to be able to grasp both ends of the pipe. To break off the section that was cut, bend the pipe. There ought to be a neat cut visible without any metal filings or dirt. If the pipe is difficult to break off, carefully cut through it using the tubing cutter.

How Do You Know Hacksaw?

1. Choose the appropriate hacksaw blade. To ensure that the hacksaw cuts through the copper pipe cleanly, use one with a tiny space between its teeth. The 32-TPI hacksaw blade has the lowest spacing between its teeth; therefore, look for one. The hacksaw will catch on the pipe if there is an excessive space between the teeth.

2. If you can, clamp the copper pipe. In case the pipe is not tight, place it in a vice such that the desired cutting position is a few inches (5 cm) away from the jaws. You will have room to cut as a result. Turn the handle until the pipe is tightly fastened and remains motionless. If you are using a narrow pipe, you might need to rotate the handle quite a little.

3. Identify the copper pipe. Choose the copper pipe’s desired cutting location. Using a fine-tipped permanent marker, mark the desired cutting location. Rubbing alcohol can be used to remove the mark from the pipe after it has been cut.

4. Ascertain the mark using the hacksaw blade. Put the hacksaw’s teeth squarely on the mark you just drew. Using your dominant hand, grasp the hacksaw’s handle while using your other hand to steady the saw’s top.

5. Sliced hard through the pipe. Bring the hacksaw back towards you while making forceful movements with the blade across the pipe to raise it. Reposition the saw blade into the grove you started cutting in, and keep driving the blade into the pipe until the cut portion comes free. Steer clear of sawing back and forth as this could dull the blade or result in a jagged cut on the pipe.

6. Wash the copper pipe that was cut. To remove any remaining metal debris from the cut pipe, use a 4-in-1 cleaning tool. Place the tool’s centre circle around the pipe and use the tool’s ends to brush inside the pipe’s end. To enable the metal bristles of the tool to clean and brush the pipe, rub the tool around its end.

An alternative is to cut a strip of sandpaper into dimensions of 1 in (2.5 cm) by 5 in (13 cm). Thoroughly pull both ends of the sandpaper back and forth while wrapping it around the pipe.

What is the Autocut Tool?

1. Choose an autocutting tool. Use an auto-cut tool when cutting copper pipe in confined spaces, such as against a corner. Get an auto-cut tool made to fit the precise diameter of the pipe you wish to cut by measuring it first. Since auto-cut tools are spring-loaded, you are unable to modify the cut’s size.

2. Secure the copper pipe with the autocut tool. Wherever you want the cut to be made, position the pipe in the centre of the autocut tool. Put the grey clamp firmly in place on the pipe. It should not be possible for the pipe to move or squirm out of the tool.

3. Make 20 to 30 turns with the tool. On the tool, look for the arrow that tells which way to turn it. With one hand, hold the pipe, and turn the tool in the designated direction with the other. To cut the pipe, turn the tool 20 to 30 times. Using the auto-cut tool eliminates the need to clean the pipe beforehand because it cuts smoothly and cleanly.

How Do You Use a Pipe Slice?

Copper pipes can also be successfully sliced with certain types of pipe slices. These instruments are sometimes referred to as auto-cut tools and typically function similarly to pipe cutters.

Because pipe slices are so small, all you have to do to use them is rotate the slice until the pipe is completely sliced. A pipe slice’s only drawback is that different pipe slices can accommodate various copper pipe diameters.

According to people who have used these pipe slices, ten to fifteen spins should be sufficient to cut a copper pipe if the instruments are sharp. If not, you might need to take extra turns.

What is the Snap Cutter?

In case you’re unaware, snap cutters are also available. To utilize these tools, simply secure the copper pipe inside the loop chain and tighten the loop’s arm. The tools are constructed with a chain.

An audible snapping sound will be produced after the copper pipe is cut. This method’s only drawback is that it occasionally causes the pipes to bend.

Advantages and Disadvantages of Stainless Steel Pipes and Copper pipes

304, 309, and 316 stainless steel pipes are frequently utilized. Every model has benefits and drawbacks.

Steel pipes are less prone to corrosion, which is one of their advantages over copper pipes. Because steel pipe does not readily freeze in cold areas, it is perfect for outdoor applications. Furthermore, steel pipes typically cost less than copper pipes.

Steel pipes, in contrast to copper pipes, have the drawback of freezing in cold weather, which can lead to issues with heating and plumbing systems. Furthermore, copper pipes are usually less expensive than steel pipes.

The superior heat and pressure resistance of copper pipes over steel pipes is one of their benefits. Furthermore, copper has better thermal and electrical conductivity than steel pipes.