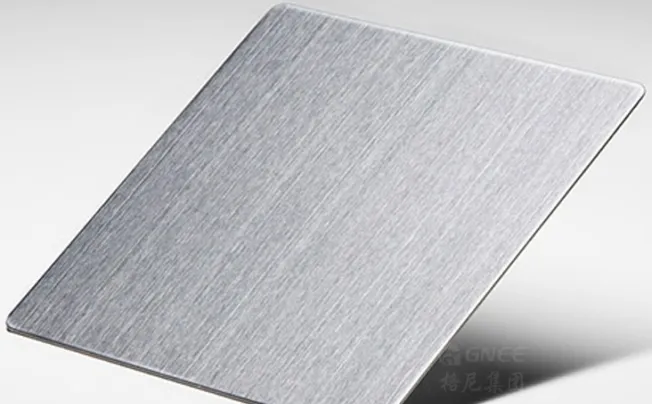

What Is Stainless Steel Wire Drawing Plate?

Stainless steel wire drawing plate, is known for its distinctive textured surface. It is a type of plate made from stainless steel plate that has undergone a wire drawing process. Wire drawing is a metalworking process in which a metal wire is pulled through a series of dies to reduce its diameter and increase its length. This process can be used to produce wires of various sizes and shapes, depending on the specific requirements.

This process, not only lends the plate a unique appearance and a most pleasing matte finish but also possesses an exceptional corrosion resistance, rendering it suitable for a wide range of applications across various industries. It can be used in manufacturing, construction, and engineering, kitchen appliances, automotive parts, industrial equipment, etc.

How Is Stainless Steel Wire Drawing Plate Made?

The manufacturing process of stainless steel wire drawing plate entails several significant steps to ensure the ultimate quality and functionality of the finished product. Here we have a look below.

1. Raw Material Selection

Usually, it uses the stainless steel plate as the substrate. But it needs to take some necessary measurements:

– Visual inspection for defects or impurities: The initial stage of quality control involves visually scrutinizing the raw materials for any visible defects or impurities. This encompasses a meticulous examination of surface imperfections, such as scratches or dents, which have the potential to impact the overall quality of the wire drawing plate.

– Testing the material’s chemical composition: To ensure the desired properties of the stainless steel wire drawing plate, a thorough analysis of the material’s chemical composition is conducted. This entails scrutinizing the percentages of various elements present, such as chromium, nickel, and carbon, to verify that they meet the required specifications.

2. Stainless Steel Material Preparation

– Before the wire drawing process, it is imperative to cleanse and degrease the stainless steel plate material thoroughly. This is done to eliminate any contaminants or impurities that might compromise the quality of the final product.

– Then, the plates will be annealed. Annealing, a heat treatment process, is employed to soften the stainless steel material, making it more malleable and easier to draw into wire form. This process entails heating the material to a specific temperature and then gradually cooling it down.

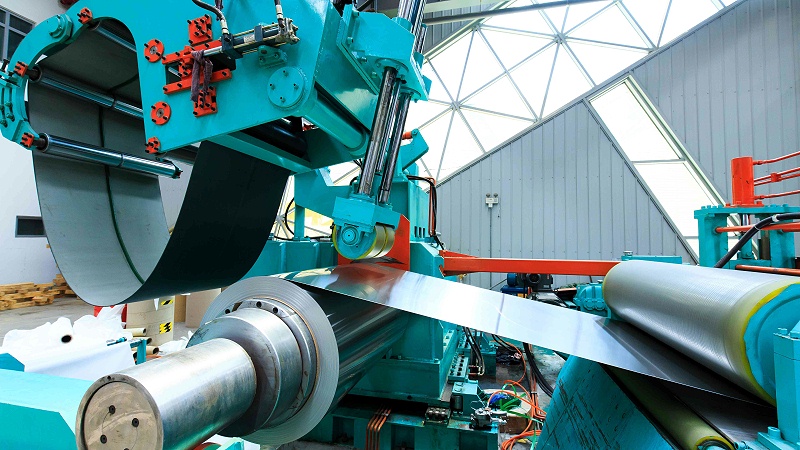

3. Wire Drawing

Wire drawing, a metalworking process, involves pulling a metal wire through a series of dies to reduce its diameter and increase its length. This process aids in enhancing the surface finish, mechanical properties, and dimensional accuracy of the wire. It has the following steps:

– Setup and Adjustment of the Wire Drawing Machine: Before commencing the wire drawing process, it is necessary to set up and adjust the machine according to the desired specifications. This includes selecting the appropriate dies, adjusting the tension, and ensuring proper lubrication.

– Drawing of the Stainless Steel Wire through Dies: The stainless steel wire is fed through a series of progressively smaller dies, gradually reducing its diameter. This process is repeated multiple times until the desired thickness is achieved.

– Repeated Drawing to Attain the Desired Thickness: Depending on the required thickness, the wire drawing process may need to be repeated several times, with each pass through the dies further reducing the wire’s diameter.

*Here are some precautions you need to pay attention to when wire drawing:

1. Monitoring wire diameter and tension: Throughout the wire drawing process, it is imperative to closely monitor the wire diameter and tension. This meticulous observation ensures that the wire is being drawn to the desired thickness and maintains the requisite tensile strength. Regular measurements and adjustments are made to uphold consistency and accuracy.

2. Checking for surface defects or irregularities: Another facet of in-process quality control involves examining the wire drawing plate for any indications of surface defects or irregularities. This entails a thorough inspection for surface imperfections, such as cracks, pits, or unevenness, which possess the potential to impact its performance and durability.

4. Annealing

After the wire drawing process has been finished, it may undergo an annealing process. It involves heating the wire to a specific temperature and then slowly cooling it. This annealing process helps to relieve any stresses in the wire and improve its ductility.

5. Surface Treatment

Following the wire drawing process, it will undergo surface cleansing and polishing to eliminate any remaining impurities and enhance its appearance. To augment the corrosion resistance and longevity of the wire drawing plate, protective coatings or finishes can be applied. These coatings serve as barriers against environmental factors, preventing the formation of rust or stains.

6. Cutting and Shaping

Once the wire has been drawn and treated, it can be cut and shaped into the desired form. This can involve cutting the wire into specific lengths or forming it into various shapes, such as plates or sheets.

7. Quality Control and Inspection

The final products will undergo rigorous quality control and inspection processes to ensure their performance and reliability. This includes:

– Visual inspection for surface finish and uniformity: Before completion, a comprehensive visual inspection is conducted to assess the surface finish and uniformity of the stainless steel wire drawing plate. This encompasses a meticulous examination of the plate for any visible flaws, such as scratches, stains, or discoloration, ensuring that it meets the desired aesthetic standards.

– Mechanical and performance testing of the wire drawing plate: The culminating stage of quality control encompasses subjecting the wire drawing plate to mechanical and performance testing. This may involve subjecting the plate to various assessments, such as tests for tensile strength, hardness, and corrosion resistance, to ensure that it meets the required performance standards and possesses the ability to withstand the intended applications.

Conclusion

Stainless steel wire drawing plate is a type of steel that has distinctive textured surfaces. Its unique manufacturing process vests its fine-line shapes and matte finish, making it suitable for various applications. It can be applied in architectural and interior design, building facades, exterior cladding, kitchen appliances, automotive parts, and industrial equipment. At Gnee Steel, we offer premium stainless steel wire drawing plates in different line patterns, including straight lines, irregular lines, corrugated lines, and thread lines. Welcome to choose the best-suited one for your projects!