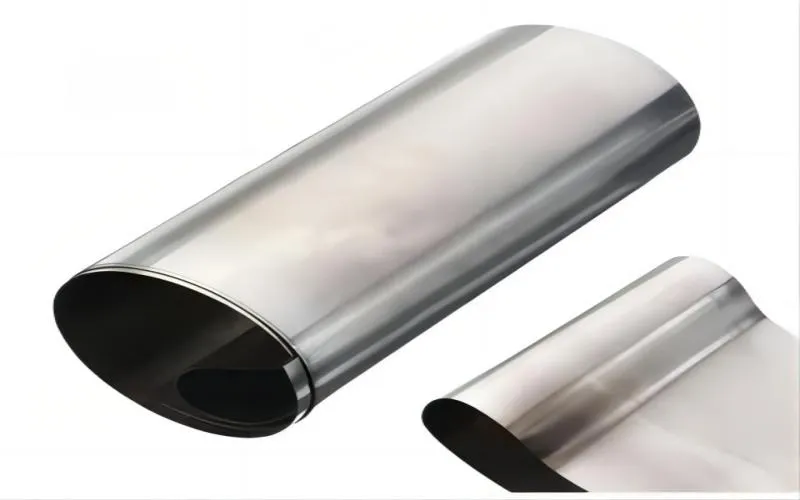

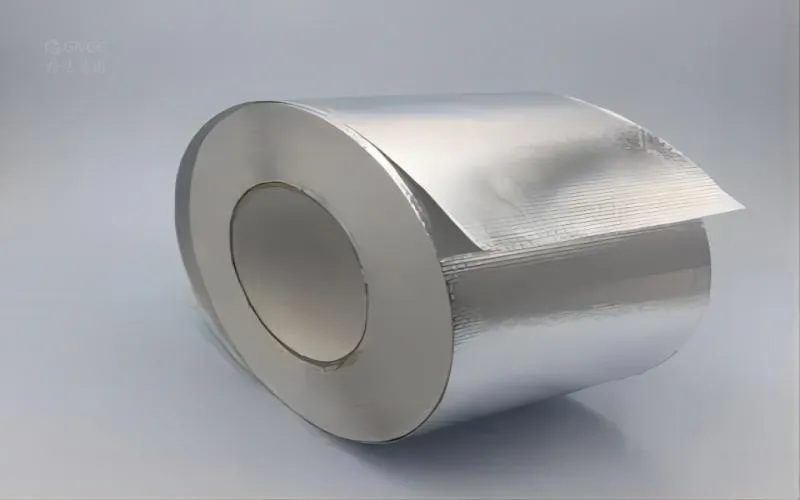

What is 316 Stainless Steel Foil?

Stainless steel foil is a thin sheet of stainless steel that is typically used for various applications due to its unique properties. Stainless steel foil is a flat, thin sheet of stainless steel that is typically less than 0.006 inches (0.15 mm) thick. It is commonly available in rolls or sheets. Stainless steel foil is primarily made of iron, with the addition of chromium and other alloying elements such as nickel and molybdenum. The exact composition can vary depending on the specific grade of stainless steel.

One variety of stainless steel foil is called 316 stainless steel foil, and it is composed of the alloy AISI 316. The elements that makeup 316 stainless steel foil include molybdenum, nickel, chromium, and iron. About 16–18% chromium, 10–14% nickel, and 2-3% molybdenum are present. Molybdenum improves the alloy’s strength at high temperatures and resistance to corrosion.

Properties of 316 Stainless Steel Foil

316 stainless steel foil is appropriate for a range of applications due to its characteristics. Key characteristics of foil made of 316 stainless steel are as follows:

1. Corrosion Resistance: 316 stainless steel foil has outstanding resistance to corrosion, especially in harsh or marine situations. It is not susceptible to stress corrosion cracking caused by chloride, pitting, or crevice corrosion.

2. Strength and Durability: The foil made of 316 stainless steel is strong and long-lasting. It can tolerate deformation in a variety of situations and has a high tensile strength.

3. Heat Resistance: In situations with high temperatures or cryogenics, 316 stainless steel foil keeps its characteristics. It is resistant to corrosion and can tolerate high temperatures without appreciably losing strength.

4. Weldability: 316 stainless steel foil has a reputation for being well-suited for welding. It works well for fabrication operations since it can be joined to other steels or metals with ease and without any problems.

5. Machinability: Compared to 304 stainless steel, 316 stainless steel foil is typically less machinable and bendable. Even so, it can still be machined with the right methods and equipment.

6. Non-magnetic: When annealed, 316 stainless steel foil is normally non-magnetic. However, when exposed to particular machining techniques or cold work, it may show modest magnetic characteristics.

What is the Difference Between 316 and 316L Stainless Steel?

The carbon content is the primary distinction between 316 and 316L stainless steel. The maximum carbon content of 316 stainless steel is 0.08%, whereas the maximum carbon content of 316L stainless steel is merely 0.03%.

Corrosion Resistance: In areas where chloride is present, 316L stainless steel resists corrosion better than 316 stainless steel. This qualifies it for use in maritime settings or regions with elevated concentrations of corrosive substances.

Weldability: When compared to 316 stainless steel, 316L stainless steel is more weldable. It can be easily welded to other steels or metals without difficulties, however 316 stainless steel is subject to weld degradation, which can weaken the binding of the weld.

Machinability: Compared to 316 stainless steel, 316L stainless steel is typically softer and simpler to manufacture because of its reduced carbon content. This might be useful in some production procedures.

Stainless steel 316 and 316L both provide exceptional strength, durability, and resistance to corrosion. They are extensively utilized in many different industries, such as chemical processing, food preparation, naval equipment, and building materials.

It’s crucial to remember that 316L stainless steel differs from 316 stainless steel in that the L in 316L stainless steel indicates a lower carbon content. The two classes differ in terms of machinability, weldability, and corrosion resistance due to the difference in carbon concentration.

Applications of 316 Stainless Steel Foil

The qualities of 316 stainless steel foil make it useful in a variety of applications.

Chemical Processing: The chemical processing sector makes extensive use of 316 stainless steel foil because of its superior resistance to corrosion. It is employed in the production of equipment that comes into touch with corrosive substances, such as tanks, pipelines, valves, and fittings.

Marine Equipment: 316 stainless steel foil is appropriate for marine applications due to its resistance to corrosion. It is utilized in the building of marine equipment exposed to extreme conditions and saltwater, including offshore platforms, ship fittings, and boats.

Food Processing: Because of its corrosion resistance and hygienic qualities, 316 stainless steel foil is frequently used in the food processing sector. It is employed in the production of processing machines, food preparation surfaces, and food storage tanks.

Medical Devices: 316 stainless steel foil is appropriate for use in medical applications due to its corrosion resistance and biocompatibility. It is employed in the production of medical equipment, surgical tools, and implants that have to be extremely hygienic and resistant to bodily fluids.

Architectural Components: Where corrosion resistance and visual appeal are crucial, 316 stainless steel foil is employed in architectural applications. It is utilized in buildings and other constructions for handrails, roofing, cladding, and ornamental features.

Heat Exchangers: Because 316 stainless steel foil resists corrosion and high temperatures, it is utilized in the production of heat exchangers. In heat exchangers, it is applied to the fins or plates that transmit heat between fluids.