How to Cut Stainless Steel Plates — Step by Step Guide

Step 1: Preparing the Workspace

Irrespective of how you cut stainless steel plates, the first thing you should do is to prepare for your workplace.

For this step, you need sturdy sawhorses or a flat surface like a workbench. It helps to clamp the sheet metal, otherwise, it will cause your cut to be inaccurate and can also be dangerous.

If you work indoors, make sure that there are no combustibles in the room as the cutting process makes a lot of sparks which may cause a fire; If you want to use a grinder, saw, or plasma cutter to cut stainless steel plates, it’s best to work outside or in your backyard.

Further, clear away any debris or obstacles that may hinder your movement or cause accidents.

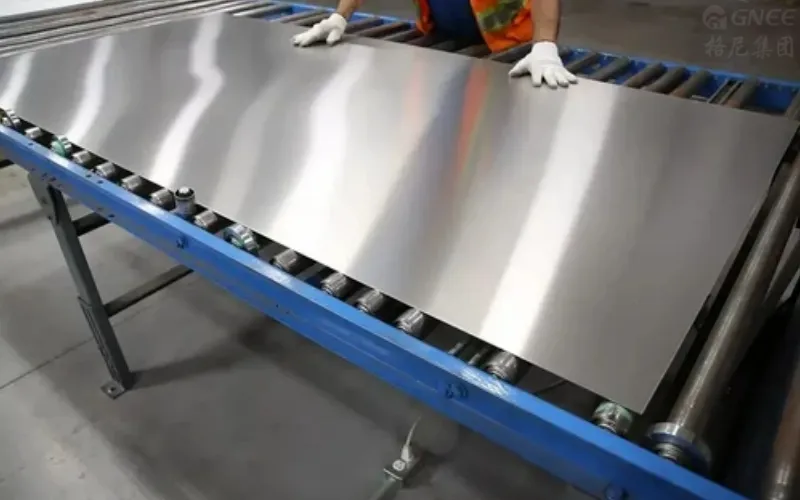

Step 2: Securing the Stainless Steel Plate

Place the stainless steel piece on a stable work surface, and use clamps or a vice to secure it firmly. This will prevent the metal from moving during the cutting process and ensure a straight cut.

Step 3: Measuring and Marking

You should use a tape measure to give your material an accurate measurement of the regions you want to cut. After that, use a marker or a scribe to mark the areas you want to cut. It is of utmost importance to ensure that the cutting line is distinctly marked and readily discernible to avoid any errors during the cutting process.

If you’re going to be cutting a straight line, use a ruler or square to get a perfectly straight line.

Double-check your measurements.

Step 4: Suiting up With Your Safety Gear

Before cutting, put on your safety gear to protect yourself from potential hazards.

Always prioritize safety and follow the operation guidelines.

Don’t forget to use a dust mask to avoid inhaling fumes and dust particles which may badly affect your health.

Step 5: Choosing the Best Tool

The next step is to decide on which tool you want to use.

If you’re cutting through thin stainless sheets, tin snips are your best option. Thicker plates will require power shears, a circular saw, or an angle grinder. For really heavy-duty stainless steel plates, a plasma cutter is your best option.

Step 6: Cutting Stainless Steel Plates

When cutting, remember to slowly and steadily cut along the cut line. Apply steady pressure to the tool to maintain a consistent cutting speed. Avoid forcing the blade through the metal, as it can cause the saw to overheat and wear the blade prematurely. Continue cutting along the marked line until you have completed the cut. Make sure to keep your hands clear of the blade!

Step 7: Ensuring Proper Ventilation

During the process of cutting, it is not uncommon for stainless steel plates to emit fumes and smoke that may prove deleterious if inhaled. Hence, it is of utmost importance to ensure that there exists proper ventilation in the cutting area, to expel these noxious fumes and maintain a safe and salubrious working environment. This can be achieved by utilizing exhaust fans or by laboring in a well-ventilated space.

Step 8: Clean Up the Edges

It’s normal to have rough edges after cutting your stainless steel plates. The amount of fraying will vary depending on which tool you use. To that effect, you have to create extra time to give your workpiece extra finishing.

You can use a metal file or a deburring tool to remove the rough edge from your material. Then, smooth the cut surface of the stainless steel plate. This can be achieved through the utilization of abrasive materials like sandpaper or grinding wheels. Finally, clean up the work area and remove any metal scraps or debris.

Remember, these steps provide a general guideline for cutting stainless steel sheets. The specific techniques and tools you use may vary depending on the thickness and size of the sheet and the complexity of the cut you require. Always refer to the instructions and follow proper safety precautions throughout the cutting process.

What Precautions Should You Pay Attention to When Cutting?

All must be safe for cutting operations. This is because an accident can cause a serious mishap when you work with cutting tools. Here are a few hints on the best way to make yourself and your workplace safe:

Keep your workspace tidy for easy mobility.

Light up your work area properly.

Place your power cables properly to avoid tripping over them.

Watch out for overheating (Overheating can easily lead to increased wear of the blade, which is not conducive to accurate cutting).

It must be carried out by skilled workers.

How to Choose the Best Tool for Cutting Stainless Steel Plates?

As we discussed in the last blog post, there are many ways to cut stainless steel sheets: 9 Main Methods to Cut Stainless Steel Plates. With so many options available, this can seem like a daunting task. But you can think about it from the following perspectives to pick out the best tool:

1. Plate thickness. Different cutting options are available for different stainless steel sheet thicknesses. Steel with a gauge lower than 18 is probably best to be cut with shears or even snips. Thicker steel is better cut with a plasma cutter, circular saw, or grinder.

2. Precision. How precise of a cut is needed? Waterjet cutting results in a precise edge, while laser cutting is effective for creating small holes.

3. Pattern complexity. If you need to create intricate designs and cut complex shapes, laser cutting is the way forward as it creates precise cuts with minimal distortion.

4. Edge quality. Many steel plates require secondary processing for refining corners and edges after cutting. Plasma or laser cutting usually produces clean edges that don’t require further processing.

Frequently Asked Questions

1. Why Stainless Steel Plate is Hard to Cut?

Stainless steel plate is harder to cut than some other materials due to its composition and mechanical properties. Stainless steel plate is an alloy of iron, chromium, nickel, and other elements that give it its corrosion resistance and durability. The high chromium content makes the steel more resistant to heat, wear, and staining, but also harder and more challenging to cut. Additionally, stainless steel plate often has a high level of hardness, which makes it more difficult to cut.

2. What Coating is Best for Cutting Stainless Steel Plates?

The best coating for cutting stainless steel depends on the specific application, type of cutting tool, and desired outcome. However, some common coatings that are known to improve the cutting performance of tools when cutting stainless steel include:

1. TiN (Titanium Nitride). TiN coating provides increased hardness and heat resistance, making it ideal for high-speed machining and cutting of stainless steel.

2. TiAlN (Titanium Aluminum Nitride). This coating provides even higher heat resistance than TiN, making it ideal for cutting stainless steel at high speeds and high temperatures.

3. CrN (Chromium Nitride). CrN coating provides excellent wear resistance and a high level of hardness, making it ideal for cutting stainless steel in demanding applications.

4. AlTiN (Aluminum Titanium Nitride). AlTiN coating provides high hardness and heat resistance, making it suitable for cutting stainless steel at high speeds and temperatures.

Gnee Steel – Your Expert in Cutting Stainless Steel Products

Do not hesitate to contact us and inquire about cutting stainless steel sheets or other materials like carbon, aluminum, copper, steel, etc.

Gnee also offers stainless steel surface treatment services: grit, brushed, HAIRLINE, embossed and mirror polishing, bead blasting, PVD, LIC, and AFP coating.

Contact us now and discover our full range of steel services to our customers.