Understanding Stainless Steel Sheet Firstly

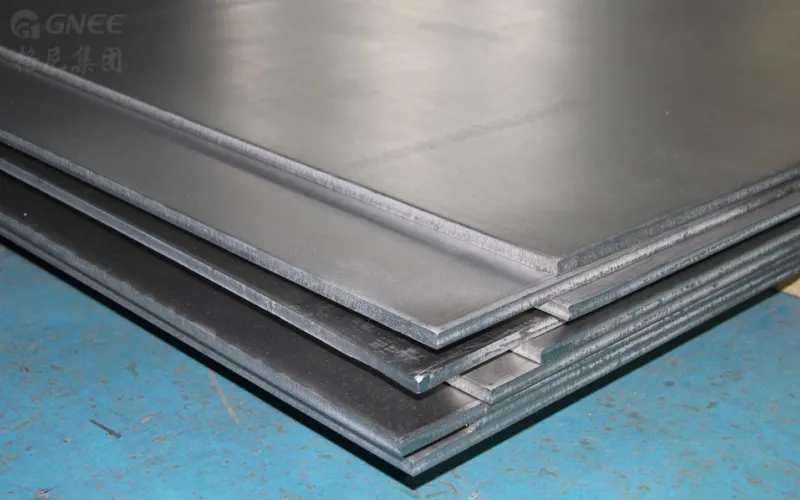

Definition and Characteristics of Stainless Steel Sheet

A stainless steel sheet is a flat and thin form of stainless steel. It is composed primarily of iron, along with a minimum of 10.5% chromium content by mass, which forms a protective layer on the surface called the passive film. This film prevents oxidation and corrosion, making the stainless steel sheet an ideal material for various applications requiring hygiene, beauty, and longevity.

Stainless steel sheet is available in various grades such as austenitic (304, 316), ferritic (430), martensitic (410), and duplex (2205). Each grade possesses distinct properties that suit different environments and requirements. For example, austenitic stainless steel sheets are non-magnetic with excellent formability while ferritic stainless steel sheets have higher resistance to stress corrosion cracking.

Manufacturing Process and Thickness Variation (Up to 6mm)

The manufacturing process for thin stainless steel sheets is cold rolling. In the cold rolling process, stainless steel coils undergo repeated passes through a series of rollers at room temperature. This compression reduces the thickness of the sheet and improves its surface finish at the same time. Then, it will be cut to create the stainless steel sheets that meet the customer’s requirements. Cold rolling allows manufacturers to produce thin stainless sheets with precise dimensions (up to 6mm) and consistent mechanical properties.

Common Applications of Stainless Steel Sheet

Stainless steel sheets can find extensive uses in various industries thanks to their versatility and unique characteristics, including:

Kitchen Appliances and Utensils: They are commonly used in manufacturing kitchen equipment and utensils owing to their hygienic and corrosion-resistant nature. From sleek countertops to durable sinks and tables, it provides an attractive and long-lasting solution for domestic and commercial kitchens.

Automotive Industry: In the automotive industry, stainless steel sheets are utilized for various purposes. They can be utilized to produce exhaust systems, engines, silencers, catalytic converters, vehicle frames, trim components, etc. The resistance to high temperatures and corrosion exhibited by stainless steel sheets ensures longevity even under harsh conditions.

Architectural Structures and Decorative Applications: It is also an ideal selection for architectural applications, including both interior and exterior installations. From exterior building facades to interior design elements such as wall panels, elevator doors, handrails, and decorative screens – stainless steel sheets offer great durability along with a modern aesthetic appeal and weathering effect.

Exploring Stainless Steel Plate Next

Definition and Properties of Stainless Steel Plate

A stainless steel plate is a flat and rectangular piece of stainless steel that is typically thicker than a stainless steel sheet. It is primarily made up of carbon, chromium, and other elements such as manganese, nickel, and molybdenum. These additional elements improve the performance of the plate in harsh environments by providing increased corrosion resistance to chemical reactions, heat, and pressure.

Moreover, stainless steel plate is well-known for its superior strength, longevity, and anti-corroding performance. It can exhibit excellent mechanical properties like high tensile strength and great impact resistance. It can also keep its shape even under heavy loads and extreme temperatures/conditions. Stainless steel metal plate similarly offers a superior aesthetic and appealing surface due to their sleek and lustrous surface finish.

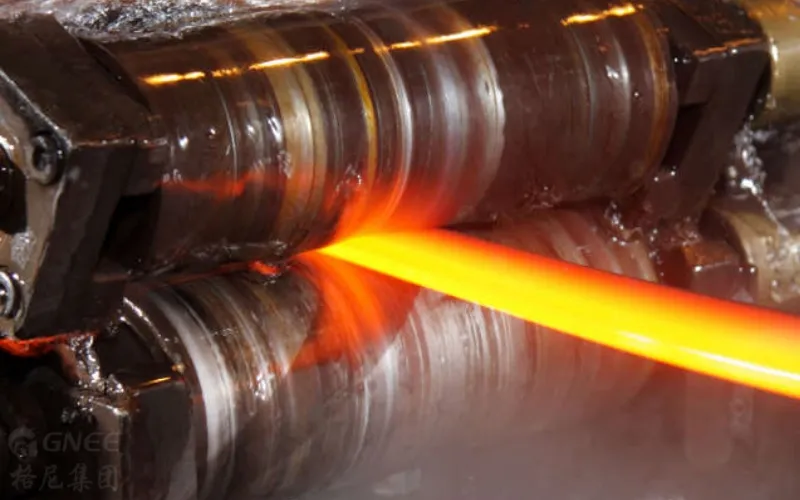

Production Method and Thickness Range (above 6mm)

Stainless steel plates are usually manufactured through a process called hot rolling. This involves heating large metal slabs above their recrystallization temperature and then passing them between rollers multiple times to achieve the desired thickness. The hot rolling technique not only shapes the material but also refines its grain structure throughout the plate. It can also remove any residual stresses or imperfections from the material, resulting in homogeneity and improved mechanical qualities.

The thickness range of stainless steel plates mainly starts from around 6 mm (0.24 inches) up to several inches. Custom sizes can be produced based on the customer’s specific project requirements.

Common Uses of Stainless Steel Plate

Stainless steel plates are used in many different industries because they are strong, durable, and look good. They also do not rust easily. Some common uses include:

Machinery Industry: Stainless steel plates are utilized for fabricating components that can withstand extreme conditions and corrosive environments. For example, it can be used in the production of oil & gas exploration machinery, chemical processing equipment, food containers, steel manufacturing machines, storage tanks, and other similar items.

Shipbuilding Industry: Stainless steel plates play a significant role in ship construction by providing sturdy hulls that can endure harsh marine environments. They are also used in creating decks and bulkheads where durability, strength, and corrosion resistance are paramount.

Construction Sector: Stainless steel plates find application in constructing bridges due to their load-bearing capabilities and resistance to corrosion caused by weather conditions. They are also used as structural supports in buildings where strength is essential.

Stainless Steel Sheet Vs. Stainless Steel Plate, What are the Differences?

From what we’ve introduced stainless steel sheet and plate above, there are truly some distinctions between them we can realize. They can be embodied in the following aspects:

Thickness Variation: SS Sheets are Typically Thinner than SS Plates

One of the key distinguishing factors between stainless steel sheets and plates is their thickness. Sheets are generally known for their slim profile, ranging from ultra-thin slices measuring only 0.4 mm to around 6 mm in thickness. These thin sheets are manufactured using the cold rolling method, where stainless steel coils pass through a series of rollers that gradually reduce the gauge.

On the other hand, plates start where sheets end in terms of thickness. They can be several inches thick and are typically created through a hot rolling process. This method involves heating stainless steel slabs above their recrystallization temperature and passing them through heavy-duty rollers to achieve the desired dimensions. The hot rolling process ensures that plates possess superior structural integrity, making them ideal for applications requiring increased strength and durability.

Size Dimensions: SS Plates are Generally Larger than SS Sheets

Apart from thickness variation, another significant dissimilarity between them lies in their size dimensions. Sheets are commonly available in standard sizes such as 4×8 feet or smaller, which make them convenient for various applications without the need for further cutting or customization.

In contrast, plates offer greater flexibility when it comes to size customization. They can be cut into different shapes and dimensions as per specific project requirements using techniques like plasma cutting or waterjet cutting. This ability to tailor plate sizes renders them suitable for diverse industries and installations where precise measurements play a crucial role.

Fabrication Diversity: SS Sheets are Cold Rolled while SS Plates are Hot Rolled

From what we discuss above, we can find that stainless steel sheets are usually cold rolled to be thinner and shinier. In contrast, stainless steel plates have a low probability of cold rolling technique due to their thickness of more than 6mm. Therefore, plates are often hot rolled. Their different production methods also lay the foundation for their respective application fields.

Use Distinction: SS Plates are More Applied in Heavy Sectors than SS Sheets

While stainless steel sheets primarily find their utility in home and kitchen appliances, automotive components, and architecture, stainless steel plates shine in heavy machinery parts within industries like oil and gas or construction. The shipbuilding industry also relies on stainless steel plates to construct durable hulls, decks, and bulkheads due to their strength, corrosion resistance, and resilience properties against harsh marine conditions.

Nowadays, both stainless steel sheets and stainless steel plates have become an integral part of our daily lives due to their exceptional properties and wide versatility across diverse industries.

Conclusion

In conclusion, understanding the distinctions between stainless steel sheets and stainless steel plates is vital when selecting one for your specific projects or applications. While stainless sheets excel in thinner profiles ranging from ultra-thin slices to approximately 6 mm thickness, stainless plates take over when greater strength and durability are required with their range starting from above the maximum thickness of the sheet and extending to several inches. In addition, stainless steel sheets are often available in standard sizes to give convenient and cost-effective solutions; whereas stainless steel plates support customization to fulfill specific dimensional requirements. Embracing these differences allows industries spanning from construction and shipbuilding to automobiles and kitchen fabrication to make well-informed decisions based on performance criteria. If you still have some doubts, let Gnee Steel help you.